Moving Along at Shidoni Art Foundry

Here are some more pictures from Shidoni Art Foundry. If you remember, in a previous blog post the Foundry poured wax into all of the molds that we sent them. There are many. Once the waxes are poured they are gated up. Each of the pieces needs a pour cup and sprues. The pour cup will be where metal is poured. The wax spures or gates are channels where the gases can escape. Later the cups and spures will be cut away. We saw this in the last post as well. Now, all of these wax pieces need to be dipped in slurry mixture.

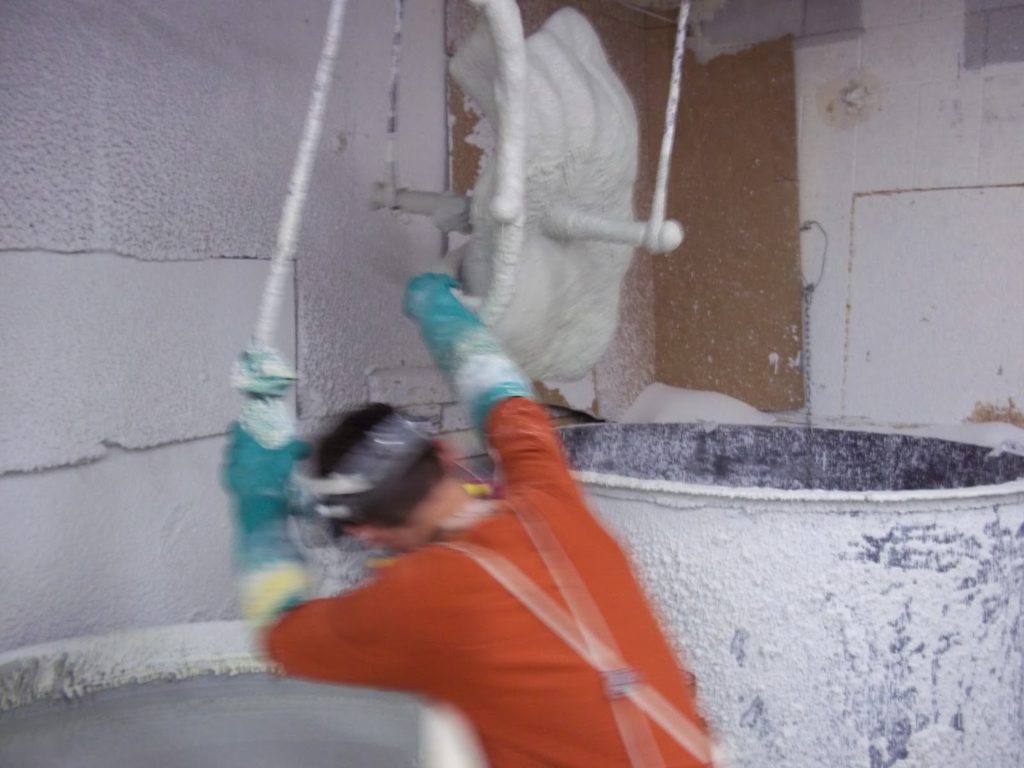

Each piece is on a pulley system, that is because they are so large. Each is carried through the wax area on this system and then lowered into the dip. Then it is covered with a sand mixture to create a ceramic shell. There are many coats of this mixture that must go on each wax piece and each piece must dry at a certain temperature. If they don’t create these shells correctly then when they try to pour the molten bronze in them later, they could break. These are all part of the rock that the Tiger climbs on. They are pretty big.