Sculpture

Moved Out of The Warehouse And Skinned A Tiger

We had all of the torso molds at the warehouse and the torso was still there as well. We literally had to skin the tiger. We separated the foam pieces from the armature and brought everything back to the studio. These will be saved until the foundry confirms they have metal.

Dental Work

Each of the pieces that make up the entire tiger, must be looked over, cleaned up and modified for making of the molds. I have saved the head for last. I’m actually quite partial to it. Part of this “modification of mold making is some dental work. I must cut out the canines to be able to get a better mold. It is a sacrifice, and in the long run, the only way this thing can come together as a bronze.

so a reciprocating saw is required.

Hard At Work In The Heat

home studio. It is good to be working back home on resin

I much prefer doing this in the fresh air instead of an

enclosed warehouse.

Though all of the remaining pieces have been moved to the studio we are still working very hard, and very long days. Remember this is a part of the foundry process that I do at my home studio. You could say that we are about 1/2 way through this process and 1/4 of the way through the entire foundry process.

multiple part mother mold in fiberglass.

to each of the pieces that are covered in rubber.

A Photo Opportunity

If the baby continues to cry sacrifices must be made!

For those of you who may not know. My daughter Christina Sizemore is my photographer. However, as past posts have shown, she has just had a baby. I am so thrilled that she had the initiative and forethought to set up a time, before we took the sculpture apart, to take photographs of me with the sculpture. The warehouse was hot and her newborn baby was with a friend in another part of the warehouse crying her little eyes out. But we got the shot. Thanks Christina and Diliberto Photo and Design. If your interested in reading her blog post on the event you can find it on her blog.

tiger was up here, but we have worked

so hard it feels like much longer.

Introducing A Grambling Intern

I was glad when I heard that Grambling State University let their students know that I would love to have interns help on this project that are students of Grambling. How incredible to be a part of creating this mascot. As my husband says, “These bronzes will be around long after we have left the earth, and even after our children and their children have left the earth.” So, working on the tiger is not only an incredible way to show how you feel about Grambling State University, but also it is a way to put you mark into something that will be here forever.

Only one student called about interning at B. Mongeon Sculpture Studios. I suppose it is difficult for many because I am in Houston, Texas. It has been a pleasure to have Joiya Smith here in the studio. She is a trooper, for she came at a time when the Tiger was already cut to pieces. She is doing the hard grunt work of helping with rubber and resin. But there are no complaints. Instead of me telling you about Joiya, here is a bit of information about her in her own words.

Hello Blog, my name is Joiya Smith from Bogalusa, La. I am a third generation of Grambling Tigers on my mother’s side and a second generation Tiger on my father’s side. My late maternal grandmother Hannah Adams and my mother Veronica Adams-Smith attended Grambling. Then my Father Robert Smith, Uncle David Smith, and other Uncle Sean Smith also attended the same university. Now I am currently here with my sister Chelsea Smith and best friends La’Derricka Morris and Sara brown. I often get asked the question “Out of all the places you have been and moved to, why did you choose Grambling?” My response is usually “ I chose Grambling because I was actually born here and then I moved away in third grade, but I knew I wanted to return home. With my father being a coach, I used to love going to the games and being around all the people, and admiring the greeks and queens. I liked it so much that I returned back to the best Historically Black College and University!”

My freshmen year back in Grambling, La has been a learning experience. I have maintained a 3.51 GPA on President’s list , joined Alpha Gamma Art Guild, The Society of Distinguished Black Women, Favrot Student Union Board, and will be serving as 2013-2014 Miss Sophomore. At the last convocation for the school year, Dr. Stacy Duhon announced about the intern to work on the school’s tiger. As an art student majoring in Digital Arts and Mass Communication, I thought it would be a perfect opportunity for me to take advantage of. So then I looked up Mrs. Bridgette’s Facebook and sent her a message. She replied with a very embracing email, with her phone number and more contact info.

I open mindedly went into the situation, I told myself whether I like it or not, I will not quit. But then the longer I stuck with it and the more days I went, I started valuing it more and more. Mrs. Bridgette told me, “it’s funny how everyone else on the campus might look at it as just a tiger, but you will see it for soooo much more.” And she is so right, I thank God for this opportunity to make history by making a tiger that will be there for a VERY LONG time. It’s great that I will be able to tell someone that I made that. The tiger is a literal and a symbolism meaning of pride. I take so much pride in the things I love, and I love my school. As I continue to my summer days working on this tiger I will continuing learning and embracing this experience!

Back At The Studio

Once all of the torso molds have been done we have moved the entire operation back to the home studio to work on the legs, head, tail and rocks. it is great to be back at the home studio with AC. It is a whirlwind of activity.

done to the tail while moving it back to the studio.

Gutting A Tiger

Both a rubber mold and a fiberglass mother mold have been applied to the torso. With this part complete we are about 1/3 the way through the mold making process of the Grambling Tiger. This week we separated these molds from the clay sculpture. Each mold had to be cleaned. The rubber is scrubbed and the fiberglass mother mold sanded. Then all of the pieces are put together. Even though we have these molds it is important to save the clay just in case something should happen to the molds. So this is our visual documentation of what is done this week.

Flipping The Kitty!

It has been a busy week. When I finally get to sit down in front of a computer to write these posts I feel so relaxed. I’m in AC. I’m not hauling, pulling, lifting or sculpting. I’m not in a hot warehouse.

We have made many accomplishments this week. The top part of the big cat torso has both a rubber mold and am other mold. See previous posts for this explanation. The big challenge was to flip the entire sculpture and take it off of the winch. The cat has not been off a winch for weeks, and it weighs a great deal more than it did going on as a foam piece. It was a challenge to figure out how we could do this, but we soon had the “kitty” flipped and supported and I began the job of finalizing the details on the big cats underside. Then we made the mold for this bottom half.

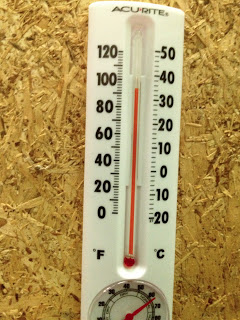

The temperature in the warehouse has reached 102. This temperature is tolerated by myself and my interns as we are forced to wear masks and long clothes to protect ourselves from the fiberglass and resin. Once this part of the mold is done we can move back to the air conditioned home studio where the paws and head await the same process. More to come.

for the final details.

Why They Call It A “Mother Mold”

working in fiberglass in the heat.

You have to wear long sleeves,

long pants, aprons, etc.

Oh, we are racing against the temperature. 97 degrees in the warehouse! This temperature is when it is less than 90 outside. Usually the warehouse is 7 degrees higher than the outside temperature. We have moved most of the tiger appendages to the home studio, and do this late at night or early morning when possible. The clay gets very soft in the heat. We will work on the appendages later. For now, we continue with this massive tiger torso.

We now need to make a mother mold of the Grambling State Tiger. A mother mold is called that because it holds the rubber in place. Mother molds can be made of a variety of materials, but we are doing these mother molds in fiberglass.

I choose fiberglass because it is lighter. The foundry that is casting this tiger is Shidoni in NM. They work on monuments all of the time. They need larger mold pieces. This is good because it makes our mold making job a little easier. But the mother molds often make the mold sections heavy, plus I will be shipping these mold pieces to New Mexico for casting so we are looking for convenience. Fiberglass mother molds win over a plaster mother mold.

Now The Real Work Begins

Many artists take their creations, once they are complete, like the tiger at the stage that was featured in the last post, and they send them to a foundry. The foundry then takes them into the foundry process. The first step of this foundry process is mold making.

Well, we do our own molds at Bridgette Mongeon Sculpture Studios. Really mold making is back breaking work, and I have had several foundries that have said they appreciate that we make our own molds.

Many ask, “how can you cut up the piece, after all of that work?”

It is very simply, it all a part of the process!