Sculpture

We Have A Tracking Number… A Tiger In Pieces From… Idaho?

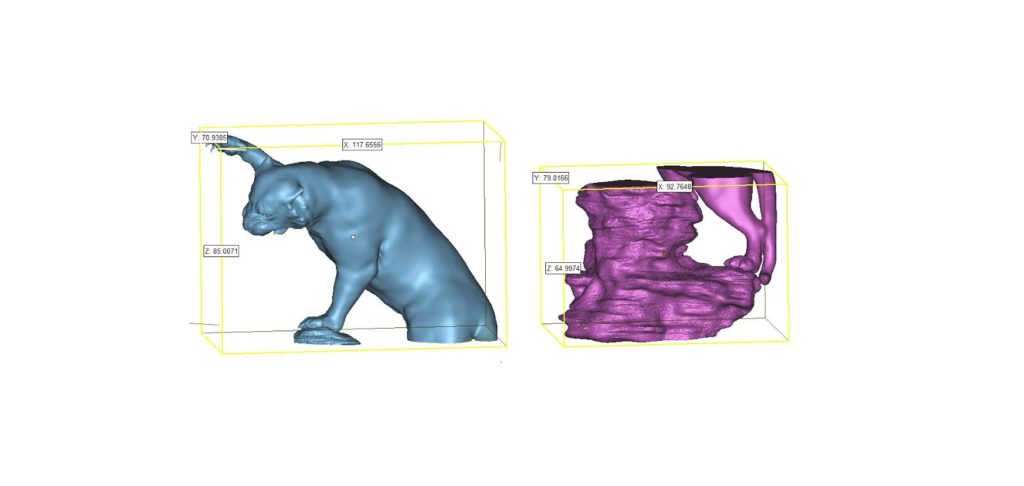

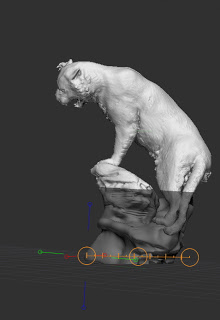

I’m thrilled to have been approached by a new vendor for this project. This vendor enlarges my tiger sculpture that sits n a virtual world in my computer and enlarges it to the size that I need it in the real world. It comes to me as a foam armature. I’ll still do lots of carving and sculpting on the piece, but having this enlargement process in foam, expedites the processes considerably.

The vendor and I have been going back and forth for the last 5 weeks, looking at digital files, changing them, comparing notes, searching for the best way to create the Grambling State Tiger. When they started milling it out they kept saying. “My word this is a big sculpture.” I believe I heard someone say, “I think this is the biggest sculpture of a cat climbing on rocks in the USA.” I’m not sure if this is true, but I’m sure I will be repeating the sentiment, “my this is a big sculpture” when the milled foam armature gets to me.

for our team. This image shows how it will be divided up.

I’m happy to say that our foam armature is on its way to us from Idaho. I expect the arrival to be Friday or this weekend, at the latest. The new vendor did send me a few photographs as they were putting the many pieces together in their own shop. Yes, the tiger is in many pieces. It will be like a puzzle for us to put them together. Will be sure to show you how our team looks as they figure out what goes where!

Bridgette Mongeon is creating this sculpture for Grambling State University. To watch the entire process you can use the categories on this blog or visit the project blog she created for the client at http://gramblingtiger.blogspot.com/

Shipping Artwork

I’m learning more and more about shipping of artwork. I have to say, as with any vendor, great customer service means the world to me. I have worked with Lace for years. She has shipped my artwork from one edge of the United States to the other, and this year gave me quotes on getting the Neil Armstrong sculpture to Moscow. When I found out she left the freight company I was using, I was painfully aware of how important it was to have someone you could call and would make sure everything was o.k. I was so excited to hear her call me from her new company.

Lace, I will follow you wherever you go. I am a fan of your customer service!

This time I’m not shipping artwork off, I’m receiving some very large piece of armature from a company in Idaho. You will see some more on that project very soon, 9 working days from tomorrow actually. As that is how long it will take to get it from Idaho to Houston.

Anytime I work on a job I learn things. For example, when crating something and needing a lift gate. A lift gate is important for me as my studio is not in a warehouse. My shipping and receiving is my home driveway – my studio is behind my home. Anyway, to use a lift gate you really should not crate up a piece any wider than 87″ or it will not fit in the doorway of the truck.

Sometimes you have to think about delivery when you are creating projects. We did this with the tiger. After I get these pieces from Idaho I’m going to have to get the entire bronze to Louisiana. lace offered some suggestions in the width of the project so that it could fit nicely on a flat bed. I hope I revised the design accordingly. I know I will count on Lace to do a good job in shipping. So, if you need something shipped, give Lace a call.

If you need to reach Lase for an estimate here is her contact information.

Acts Crating & Transportation Services

crating@actsintl.com

Lace

Acts Crating & Transportation Services

7207 B Wynnwood Ln

Houston TX 77008

713-869-2BOX (2269) work

713-969-9009 cell

713-880-3389 fax

Going To Pieces

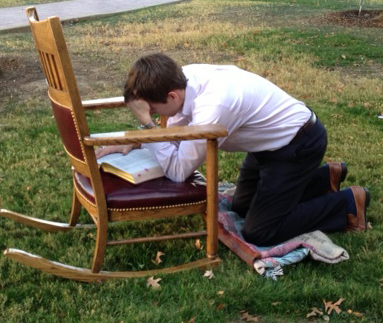

Most people reading this blog will cringe at the pictures in this post. Yes, the praying man has gone to pieces, but the foundry will put him together again.

metal, they now need to be put together.

but how else are you going to grind and weld the underside?

Bridgette Mongeon created this sculpture for Dallas Baptist University. If you would like to read the entire process on the artists project blog for this project visit http://prayingmansculpture.blogspot.com/ .

Comparing The Process Of Bronze To Prayer

As I sit and write this blog about the praying man and see the stages of the creative and bronze process I wonder if there are comparisons.Vision- action-perseverance-tenacity

I have a vision, it comes together only through a considerable amount of work. There may even be creative obstacles in the way. I have skill, to create this vision. This is something that has taken years to develop, but the other things that are necessary are the tenacity, and perseverance to get to the end. Anyone who has had a vision, or a direction they felt God had told them to go and has followed that, knows that this sometimes takes years and years. Modifications and perseverance are a must.

Approval- My perfection is not so- unless I am severed first. I spend so much time making the final sculpted clay “perfect” for my clients to see. The perfection serves a purpose, so that the clients will give their approval to go forward, but in reality it is more work. I know there are things I can do when the sculpture is cut apart that I could not do with it as an entire “perfect” vision. Maybe that is how God works with us. We try to be perfect, and feel our direction is certain, but then our experiences our lives are severed and we wonder why? It is because there is so much more God can do with the pieces than he could ever do with what appeared to be the whole.

In the garden I cut away perfect growth to make something grow fuller. How many times in our lives do we feel severed and wonder why? Trust God. Perfection and fullness is the goal.

Those first seeing the process and watching me cut apart the praying mans sculpted piece might think this is severe. I, as the sculptor, see the importance of this. I cannot make this a solid object. I cannot get it to where it is supposed to be without this part of the process. I try to reassure those reading the blog, or new artists, don’t worry- trust the process. I can also trust the process because I trust the hands that will be shaping this sculpture long after I have let go. My foundry man Miguel is incredible and I trust him with all of my artwork. I have followed him wherever he has gone, as I know that the end will be incredible. I also trust God with the pieces of my life. I guess you could say, he is my foundry man. Though I’m not sure how all of my own pieces in my life go together. I know he will make me a work of art.

stage of the bronze process. But I know each part of the

process has a place. It has limitations. I can’t reach what I

am after until I proceed through the entire process. I must

continue on to the end or I will not see the results come

together. Very similar to our walk with the Lord.

Mold- Here I have the time to clean each severed piece. Though this is still a process and I know that even though I work diligently at mold making I will still be working once again in this next stage in wax. I’ll work to try and make everything perfect or as close to it as possible. Sometimes in my life I have stopped and actually said, “Just what is you plan Lord? I know you have one, but with all that is going on it is difficult to see.” I guess I was just in the middle of God’s process of solidifying who I am. Wax-

We trust, though we may never really understanding the process.

Isn’t it strange that we go from a solid sculpture to this very fragile wax. It holds the details, it is still in pieces and much closer to perfection that it once was, but it is even more fragile. Again, I have encountered times in my life when I felt like I had the impression of what God was trying to do, however, still felt fragile. The important thing is to stick with the process. Trusting and continuing in what is set out before you.

Gating up. Without the gates added to the wax when the sculpture goes through the bronze, the metal pouring it would blow apart. Connections- The foundry man knows where to make those connections from one area to the other. God knows how to connect the parts of our life. There are things that happened 30 years ago, that I am now just seeing the importance of, the connections. Even the painful things have a different meaning when looked at from a distance.

Detail sits beneath the layers of a shell.

The creating of this shell is so important. The details are transferred to it. It needs to be strong and not have any holes in it or the bronze will not pour correctly. Do we sometimes feel that our lives are still, almost smothered? What is God doing to the details that we don’t know about? The PourI find so many comparisons between sculpting and my spiritual life. This pour means we need to heat the shell in an oven and pour molten bronze. I have a bible study I have created about clay and our walk with the lord. Even with a water based clay that is fired in a kiln the clay is useless unless it goes through this heating process. It can hold nothing. But fire it and it becomes strong. The interesting thing with the water based clay that is fired in a kiln is that the white clay before firing is actually grey, but the firing process turns it to pure white. I don’t need to compare more than that. Our trials our tribulations strengthen us and sometimes they make us feel like we are going through fire.

Bridgette Mongeon created this sculpture for Dallas Baptist University. If you would like to read the entire process on the artists project blog for this project visit http://prayingmansculpture.blogspot.com/ .

Pieces Of Prayer In Different Stages

I visit the foundry weekly checking on things. This weekend I worked on the waxes of the rocking chair when returning to the foundry the praying man is in pieces and stages throughout the area. Here is what I have seen over the last couple of weeks.

gates, and dip and sits

awaiting the pour of bronze.

The Burn Out And The Pour

The many pieces of the praying man will go through this next stage of the foundry process. First let’s recap. These are the steps that have taken place so far.

- Sculpting

- Mold making

- Wax

- Cleaning of Waxes

- Gating up

- Dipping

Gating Up And A Dip

on a shelf.They must be dipped many times.

I’m going to the foundry weekly to check on things and make sure things are looking good and that we are progressing on the sculpture. This week I saw that many of the waxes of the praying man were gated up. This means that wax rods were put in place for the gases to escape. Pouring cups were added as well. Then each of these pieces are dipped, many, many times. Depending on the humidity this can take several days. Other molds are having wax brushed in them. Still others are almost ready for a metal pour. The many pieces of the sculpture are in various stages of the foundry process.

sits in their molds while they awaiting the dipping.

of the chair are waiting my approval.

many coats of wax.

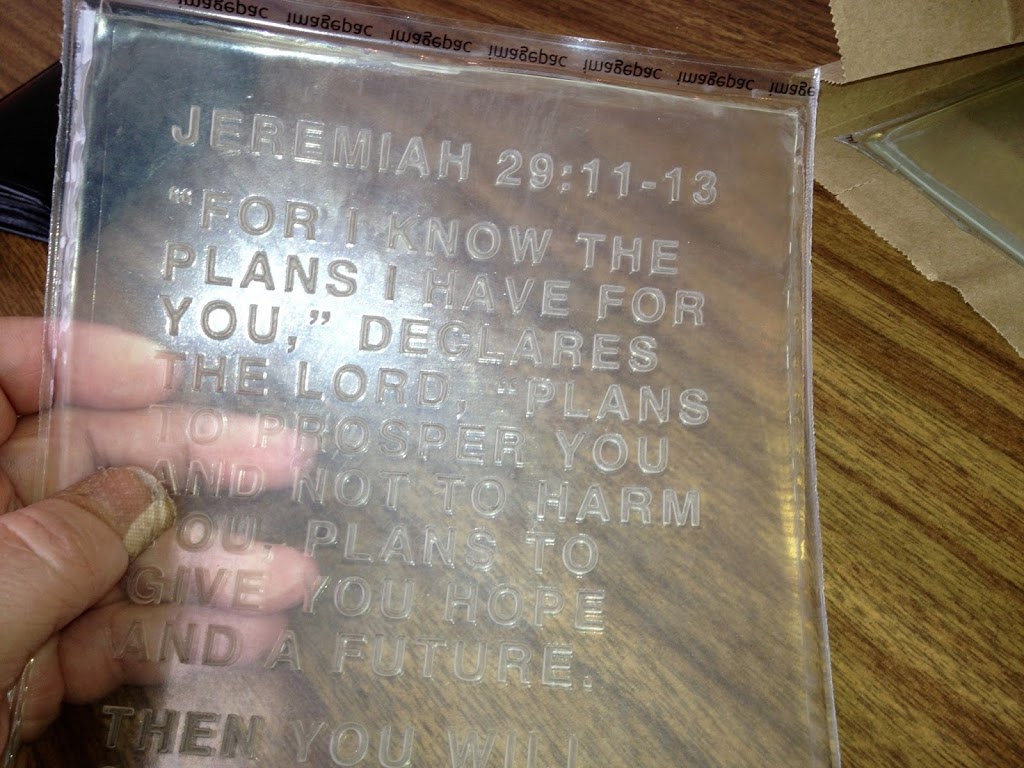

The Bible

The last and final piece to be complete for the praying man is the bible and seat. The biggest hold up with this was the text that was to be created in the bible. Usually I hand carve the text; however, this was three verses and quite a bit of text. After much deliberation I had the text created as a rubber stamp that is reversed, the type is indented into the rubber. I completed sculpting the bible and then put this stamp inside the pages, claying up to the edges.Then we made a mold of the seat and bible. THE FINAL MOLD IS COMPLETE! Everything will now go to wax and metal.

pages. Here is the seat after the mold was made.

clean the studio and get ready for the next project.

The text on the bible looks great!

Waxes—Gating Up

Once the waxes are poured and cleaned the foundry will gate them up. Gating is adding wax channels to the wax pieces so that gases can escape. A pour cup is also added to the wax.

Today I went to the foundry to check on more waxes and saw that a good deal of the praying man has been gated up.

Planning

It is safer for my interns and myself and

means that we are not held up by finding

warehouse space for a 15 foot tiger.

Now that we have the green light on the tiger I am spending a good deal of time planning. We are calling vendors and securing our schedule, and ordering materials. There was a bit of delay in getting the green light so we have to start over in this planning stage.

Besides planning vendors we are also planning the armature. Planning an armature is an important element to any sculpture. I always tell students, “if you armature is bad it can ruin your entire sculpture. ” Just imagine you are working on a large sculpture and all of a sudden it begins to fall over. In the case of the tiger, it could actually hurt someone.

An armature is what is inside the sculpture to hold it up while we are working on it. It takes a bit of engineering and a bit of history to know exactly what to do when building an armature. While I plan I send my plans off to others for them to look at and weigh in.

The main body of the cat will be milled out in foam. The foam, when it is together will probably weigh in at about 160 lbs. We will be adding wax on top of this as well as clay. This may add approximately another 300+ lbs to the piece. That is a lot of weight to be so high in the air.

The rocks are another element that has to be created. This will most likely be sculpted out of a different type of foam and then covered in clay.

We are still figuring the best way to sculpt this tiger. The artist in me says let’s put him together and work on him, which means I need a warehouse that is about 15 feet and have to move my entire studio. I like the idea of being able to see him all together. It also means I’m sculpting very height in the air, on ladders and scaffolding.

Another thought is to sculpt him in two pieces The first piece will be the rocks and his tail and back legs. The second piece will be the upper half. This way it is much safer for myself and my interns. I’m leaning in this direction. Though we will have the basic shape of foam and tiger put together before we separate these two pieces. So we will be able to see the design as a whole.

More to come. Meanwhile we are finishing up our last project and moving things around getting ready for the tiger while the vendors are getting our foam ready. Time before we receive foam should be about 3 weeks.