Sculpture

Which Way Do We Go?

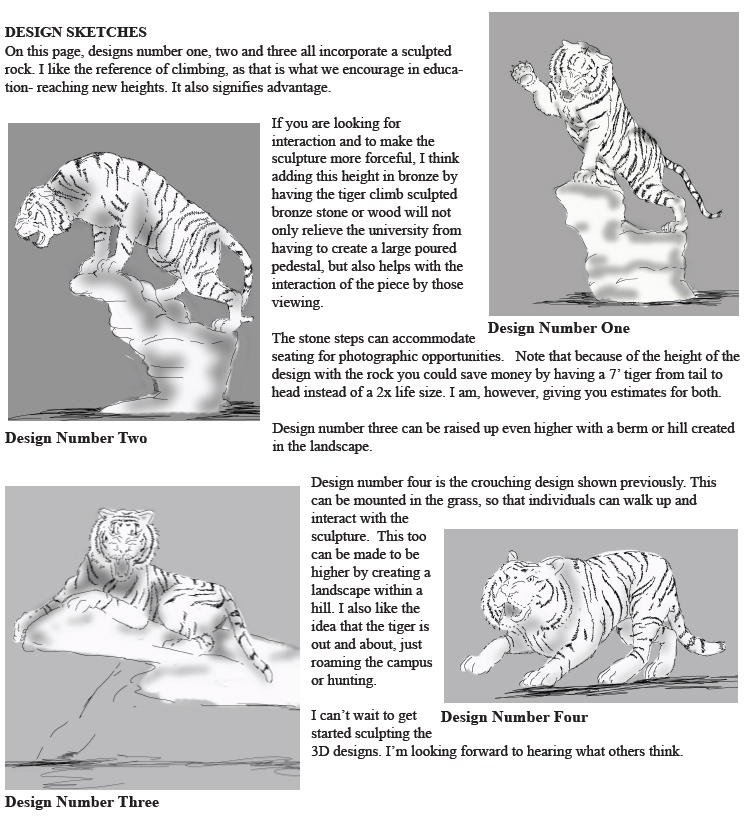

To expedite the process several quick sketches are put together for Grambling State University to look at. At this point in a project it is important to find the desired direction of a client. They might not even know what they are looking for, these quick sketches, help us to narrow down our direction.

Some of our thought process is this.

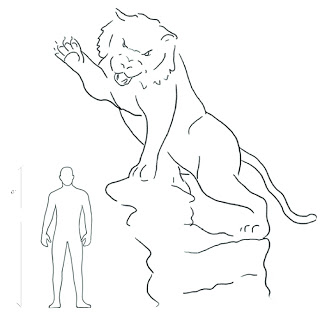

- To make the sculpture look large if we place it above, climbing on sculpted rock it will enhance the height.

- It is necessary to have a sculpture that others can interact with. I love this type of sculpture. As an artist I want people to interact with my work. I can’t wait to see pictures of people interacting. When the sculpture is done and placed this blog won’t stop. I will post what you send me. Please be sure to send the names of the people interacting. A school mascot is meant to be interacted with. Having large pedestals for sculptures suits some purposes, but for this… can someone say photo op?

- Grambling State University says they want an open mouth, a growl.

From the Grambling State University project blog at Gramblingtiger.blogspot.com

The Beginning

Welcome to the blog of the process of creating this wonderful sculpture for Grambling State University. Bridgette Mongeon, is the sculptor of this life size bronze mascot. She does her best to keep everyone abreast of what is happening with the tiger. This blog is created so that everyone can follow along.

Many times Bridgette Mongeon up to my elbows in clay, which does not work very well with typing up blog posts, but we will try to keep the blog current.

The rock looks like the state of Louisiana. That was

unintentional, but lets see how that plays out

in the sculpting process.

The Beginning-

Everything is all done in secret. A contact form comes into the Bridgette’s inbox requesting information about a sculpture and she responds. Then there is a lot of red tap to go through, contracts etc. and always a very quick deadline.

“I’m thrilled to be working with Grambling on this project. I love to capture the spirit of an entire school in a sculpture. ”

GO BIG OR GO HOME! Well not really, but that is what it appears. Bridgette presents several designs and sizes to Grambling State University. They decide they are going to have the largest size created for their campus.

From the Grambling State University project blog at Gramblingtiger.blogspot.com

What Now?

I’m working on the few waxes that are here and I expect to receive a call from the foundry that the others are ready. If I am lucky then by the end of the week the foundry will have all of the waxes and they will begin the pouring process of Evelyn. It is so exciting. For the time being, in between working on waxes, I’m resting my hands and preparing for a meeting when I bring back the photograph of Evelyn.

Oh yes, it took us two days to get the studio cleaned up and it is ready for the next project.

You can follow along with this entire process of creating a life size bronze for the ERJCC on the Evelyn Rubenstein project blog located at http://erjcc.blogspot.com/

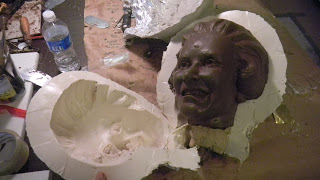

The Next Step- Waxes

Once all of the molds are at the foundry, they pour waxes. For every mold there will be a hollow think wax created. Because I finished the arms, head and base these are sent back to me first. What do I do with these? The wax stage is one more opportunity to add detail, and clean things up. Remember the rubber molds were in to parts and so there is also the cleaning of seams. Once I feel I have all of the pieces clean and that they go together correctly, we will start our process of bronze casting.

You can follow along with this entire process of creating a life size bronze for the ERJCC on the Evelyn Rubenstein project blog located at http://erjcc.blogspot.com/

I have signed the bottom.

Evelyn will be welded to this base.

The base will then be secured to the

floor of the Evelyn Rubenstein Jewish

Community Center.

Mold Making

I like that I can work on the area under

the skirt.

The mold making process is often done by the foundry. However, I create my own molds. It takes about 2 weeks of time and is very labor intensive. I’m thankful for the interns and helpers who have come to assist in the last two weeks of mold making. My husband kept coming down from his clean office and watching me tug, lift and pull and just shakes his head. My interns say it is better and more physical than working out in the gym. The mold making process consists of several steps.

1. Cutting up- This was already mentioned in an earlier post

2. Claying up- In this part of the process the mold is divided into two halves with clay seams. Pour cups are also added to the mold- This offers a place for the foundry to pour the wax.

3. Painting Rubber- Once the pieces are cut, cleaned and clayed up the rubber is painted on both halves of the sculpture. Four plus coats are used on each piece. It takes about an hour for the rubber to dry in between coats.

4. Mother mold- the mother mold is called that because it is placed on top of the rubber mold and holds the rubber in place. Without it, when someone tried to pour wax into the mold the mold would be miss shapen. Creating the mother mold is hard work. A very stiff plaster/cement is mixed for each half. I mix my plaster by hand. It takes about 40 minutes for each half of the mother mold. Everyone of the molds that I made had at least 2 mother molds- front and back. The chest had three because it was so large.

You can follow along with this entire process of creating a life size bronze for the ERJCC on the Evelyn Rubenstein project blog located at http://erjcc.blogspot.com/

coats of rubber.

to be sent to the foundry .

How Do I Stay Focused While in The Studio?

Thought I would share this little tidbit. I stay focused by….

Listening to audio books. I’m pretty much addicted to audio books and have a regular relationship with my library.

I also have the company of a very faithful, yet somewhat stinky old dog. And when I need a break I head outside my door and hang out watching the turtles at my pond.

watch nature for a moment.

Now For The Next Part Of The Process- Mold Making

The sculpture is divided into 8 pieces.

Once the approval is received, I then begin the next step. Even though I have spent hours painstakingly putting in all of the texture and detail, I must now cut up the sculpture. In the end there will be molds made of the following.

1. left arm

2. right arm

3. toros

4. head

5. two parts of skirt

6. left leg

7. right leg

8. base

The best part of cutting the sculpture apart is that I can work on the detail so much easier. For example, I work on the detail on the underside of the hands. This means that all though I have approval I still am spending an entire week on making parts as perfect as possible. While working on the hands, I found some chord and was able to make a better wedding ring, and give Evelyn a manicure.

You can follow along with this entire process of creating a life size bronze for the ERJCC on the Evelyn Rubenstein project blog located at http://erjcc.blogspot.com/

The Changes That Were Made

Here is the larger photograph that was provided that had so much more visual information. I separated the head from the body more time, so that I could really get close to it. Someone asked me how many times I have done this in the process? I have no idea, too many times to have kept count. The reason why I do this is that having a head in my lap is much easier than trying to sculpt while it is attached. I changed some things on the sculpture like the eyes, and tweaked the smile I also elongated her neck.

I also worked hard on the legs. I thought it important to give the sculpture a little more movement.

You can follow along with this entire process of creating a life size bronze for the ERJCC on the Evelyn Rubenstein project blog located at http://erjcc.blogspot.com/

Client Approval

I know some artists might not like client input- I LOVE IT! I really do.It is at this point when we are pushing the creative process to the very limit. I love co-create with my client. The interesting thing about this creative approval is that the client brought the photograph that you see on the right of this page, but it was a bigger version. Why would this matter? Well there was so much more visual information on the larger photograph. Good photographs cannot be overemphasized when trying to create.

You can follow along with this entire process of creating a life size bronze for the ERJCC on the Evelyn Rubenstein project blog located at http://erjcc.blogspot.com/

Approval Of The Sculpture

I have not posted anything in the last couple of weeks and have done so on purpose. I wanted my client to come by and see the sculpture themselves. I am happy to report they are very happy with the outcome, which I will post soon. Just a bit more tweaking and then you will be able to follow the process of going through the foundry. More to come soon.

You can follow along with this entire process of creating a life size bronze for the ERJCC on the Evelyn Rubenstein project blog located at http://erjcc.blogspot.com/