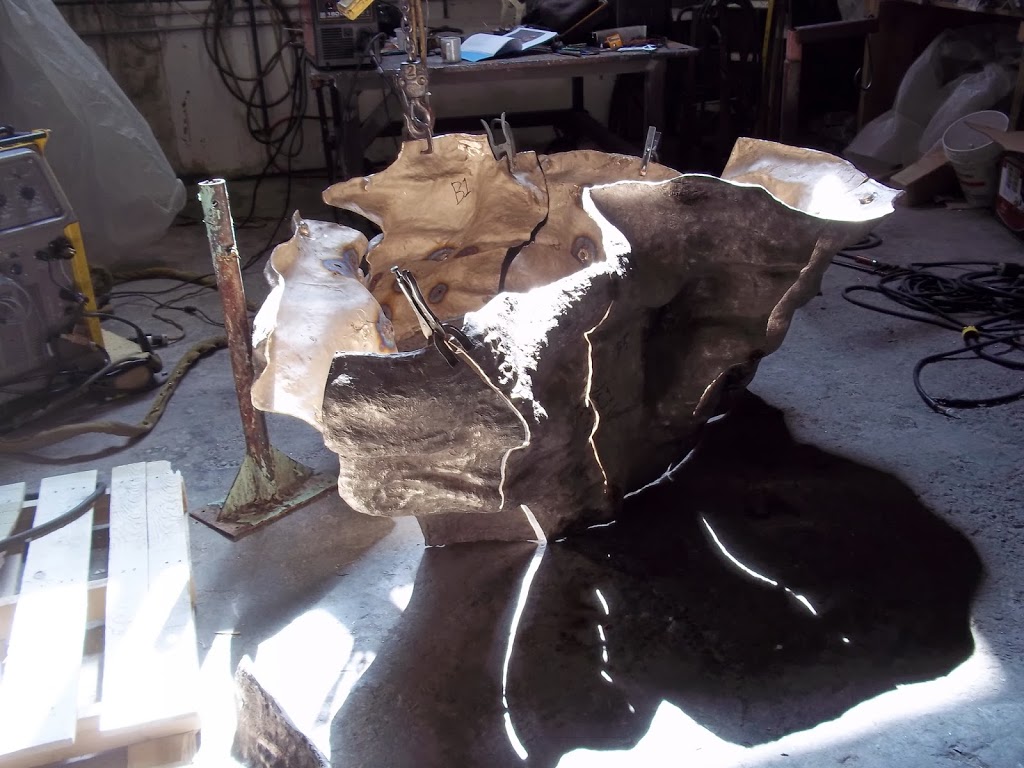

Rocking Out! Putting Together The Tiger Sculpture In Metal

There is still much to do with the tiger. If you have been reading this blog you have found that the process of creating a mascot is quite laborious. Here is the process with links, once again. Note: there are a lot of other posts of the process in between all of these links below.

- The First blog post –The beginning June 1, 2012 The blog begins.

- Design process June 17th – The designing and working on project begins long before the actually sculpting.

- Approval process January 23rd- Approvals and final paper work is received by client.

- Enlargement of Design January 23rd – The enlargement of the sculpture is being made into foam for us to sculpt on. Meanwhile we search for a warehouse to hold this big creature.

- Foam Armature arrives in Houston. The CNC milled foam gives us an armature to sculpt on and arrives in Houston in March

- Approval of Sculpture May 27th post. Which means we have sculpted this huge cat in 2 months! this would never be able to be done without the digital technology of CNC milling to enlarge the foam pieces. It is a huge accomplishment. There were many interns who worked endless long hours.

- Mold making The sculpture comes a part and we begin the first part of the foundry process the mold making.

- Molds shipped to Shidoni art Foundry July 27th They will finish the foundry process.

- Wax and Sprues or gates Beginning in August the Foundry makes waxes from the molds.

- Pouring of metal- The pouring of metal happens each weekend at Shidoni art Foundry.

This is what we have accomplished thus far. In the next few weeks the last steps will take place

- Welding

- Patination

- Delivery

- Installation

Here you can see that the many, many bronze pieces that are poured are now welded together.