Education

More Metal Question.

I’m trying to get my head around the digitial printing in metal. In my November 22 post I have shown two videos. The second one though it says shapeways is exones process. I posted the first one because it helped to clarify things for me though I was told the first video is not really how they create their bronzes. Ex one tells me their bronze is Our bronze is 90% copper and 10% tin. I have been talking with them about collaboration on the book and project. This is something I received from the production company at ex one 60% stainless steel

40% Bronze

“We print in a bed of stainless steel powder layer after layer until the three-dimensional part is done. We cure that bed of powder and then we take bronze powder and wick it into the bronze metal. How this happens is as follows. The design that was printed has a stilt as we call it (nothing more than an appendage sticking out of the part). This is added before we print in the stl file. When we set up the furnace we take that stilt and touch the bronze powder to it. At a certain temperature in the furnace the bronze powder starts to melt. When that happens the bronze capillaries into the stainless steel. If you would look at the stainless steel object before the bronze in infiltrated it would look like your kitchen sponge. A sponge has holes all over it. Same principle for the stainless steel part. So in order to fill those holes we use the bronze which is a lower temperature metal to fill the voids. This is how it becomes a composite.”

My question would be this. How would this weld together? If you printed in pieces and welded it together could this be seamless? would the welds show over time? ( this is a horrible thing concerning a fine art bronze) I wish I knew a metalurgist who could look at an ex one piece and compare it to the Everdur bronze. I’m also curious how this “printed metal” will handle the outdoors.

Learning About Retoplogizing—An Excellent Video!

Can I Really Digitally Print In Metal?

This is an excellent video that discusses Powder Metallurgy.

I know it seems like it is something that is not affordable not doable for the average person. But shapeways is making this connection to the common artist, the every day guy. Check out this video

And their prices are extremely affordable. http://www.shapeways.com/

3D Camp Houston Was A Success. Next Year Bigger And Better.

It was last Wednesday that my husband invited me to the 3D modelers and animators meetup. I was interested in the presentation on Zbrush by Johannes Huber. It was there that I met David Morris. David told me about a project he had been working on for just 8 weeks. It was a 3D camp, planned for this past weekend. He envisioned a place where people could get together and talk about 3D. My husband Mike delaflor and I jumped on board.

David was doing exactly what I wanted to do. I had actually been thinking about this for a year. I was going to do it this fall, but instead decided to perhaps make it a part of my graduate practicum. I had already talked to Next Engine, who have some wonderful affordable desk top scanners. Ex One who you have seen in previous posts. I have been contacting them about their direct metal printing and last month I went to see there printing sandcasting Molds. Ex One said when I was ready to get this going they would try to get Shapeways on board. For those of you who don’t know about Shapeways they are affordable service bureau for 3d digital printing, and they too are now offering digital printing in metal!

My goal was to get some vendors there and also offer some informative lectures on different processes of 3D. Well David did just that with 3D camp. I’m so excited and totally impressed with this young man. I think you will see this 3D camp grow in the up and coming years. I’m looking forward to presenting next year, and hopefully get the above vendors to demonstrate.

This year I demonstrated the 3D scanner, though I must say it was a crowded area and hard to get a good scan with so many people bumping the table. Still I get was able to sing the praises of this scanner that we are reviewing and using in our up and coming book, Digital Sculpting with Mudbox: Essential Tools and Techniques For Artists.

I also had this video playing and my article that I wrote for Sculpture Review on digital printing and milling where I talked about the incredible advances of Synappsys digital printing and their Data Direct to Mold process that is being used on The American.

My vantage point of 3D is coming from a traditional studio and using it to create traditional art. I suppose my focus then is a bit different than the traditional 3D artist. My graduate studies at Goddard- A Master of Fine Arts In Interdisciplinary Arts is based upon bridging the gap between the traditional and the digital studio. That is my interest. Though I have to admit, programs like Mudbox and Z brush are very intriguing and I expect I will be using them much more in the future. Oh no am I converting? Still I like the clay under my nails and my heart longs for dirty hands.

I encourage others to get involved with 3D camp next year, and plan on attending. I’m expecting it will double if not triple in size with a year of planning, some more backers, and some good promotion. If you would like to be a sponsore, If you are interested in presenting or are a vendor that would like to show at 3D camp next year please feel free to contact me or David.

Great job David!

Some of my favorite things there revolve around output. This is a home made cnc router machine. To check it out further go to http://buildyourcnc.com/default.aspx

Many seemed to be interested in what a fine artist had to say in a 3D camp.

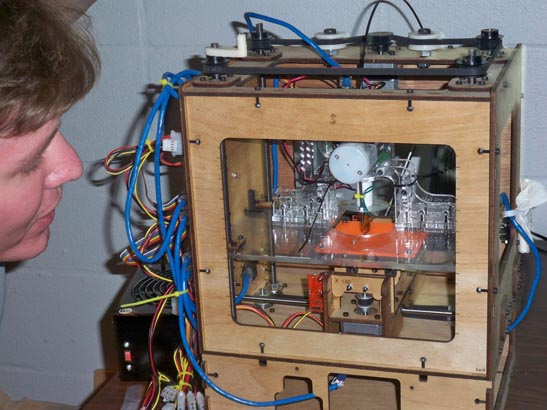

Another of my favorite had to again deal with output. It is the homemade 3D printer. This one is called the cupcake, and I must show that it can print a cupcake. I believe the cupcake costs about 700. to put together. There is another homemade one that I want to investigate but it costs approximately 3,000. Kind of steep to do for a hobby or to check out, but this other can print ceramic and chocolate, something worth investigating. I plan on reviewing all of these home made machines in an upcoming article.

3d Printing In Ceramic!

I’m looking forward to working with Solheim Rapid Prototyping/ Rapid Manufacturing Lab at the University of Washington’s Mechanical Engineering Department, collaborating and certainly want to add their process to the new book that I intend to write, my articles and a lecture. I love seeing video and am certainly glad that this was created. I will be trying to contact them on their process and new technology and will be sure to let you know what comes from that.

I’m A Genius! 3D Printing Of The Human Organs?

I’m a genius, or maybe my brain just thinks such radical thoughts that now and again I think like a genius. For those of you who don’t know, my graduate study at Goddard College consists of research that bridges the gap between the traditional studio and new technology. For a sculptor, such as myself, this technology is based on something that I call tradigi sculpting which utilizes both traditional and digital means to create artwork. My research is evaluating digital milling. Digital milling is taking my artwork, scanning it and then enlarging or reducing it to be milled out in foam, wood or stone. Digital printing is another resource and a technology that is quickly growing and changing. It is when a computer and a digital printing machine slowly prints, layer by layer, in 3d. What you end up with is a physical object. Yes, I know it sounds like the replicating machines on Star Trek, but this is not science fiction.

Recently I uncovered the work of both Sebastien Dion from the Center for Applied Technology at Bowling Green University in Ohio and Solheim Rapid Manufacturing Laboratory at the University of Washington in Seattle. Both have been researching and printing in ceramic. Solheim has even printed their ceramic “recipe” in the Ceramic Arts Daily, February 1, 2009, article “The Printed Pot.”

As my research continues, I thought, “It appears that 3D digital printing is all about having the right “recipe”. It is just coming up with the correct binder and the correct material to fuse.” This is where my brain started to go into genius mode and my research landed on what I’m about to share. I know that Science is using 3D printing to help them visualize scientific data. For example space physics simulations or molecular models that help scientists visualize proteins. This allows scientists a way to examine information in a physical way that has never been available to them prior to 3D printing.

Science is also using 3D printing to print a medical implant that fits perfectly with a patient. The reason is that it is created from MRI scan data of a patient. ) Surgeons can also use 3D printing to help them with their surgeries. By having the physical replica of a patient they can practice surgery or see complications. 3D prints are also used in education. How about printing skin in a 3D digital printer? Just think what this would mean to a burn victim. Or how about replicating a bone with 3d printing? And doing so out of bone material to replace a patient’s own shattered bone? Because our bodies are symmetrical a left arm bone could be recreated by using images of the right arm.

If all of this technology and 3D printing is not fascinating enough, I thought, “If it takes just the right binder and recipe, is it possible to print organs?” I was afraid to even say it out loud to my husband, a medical illustrator, who I knew would at least hear my crazy idea and not laugh too hard. But with further research, I turned out not to be so mad after all. Indeed 3D organ printing is happening or at least being studied. Here are some journal articles and videos to prove it. This is absolutely fascinating! Just check out the video with Dr. Gabor Forgacs, University of Missouri-Columbia. He talks about how the bio printer prints out living cell clusters drop by drop that fuse together to create tissue structures. Have a damaged organ? One day they will be able print out the organ needed and do it using your cells! Perhaps the printer will print within your own body cavity. Yes, there is still some headway to be made with this technology, but the technology is here and on it’s way. My crazy thinking is actually genius!

by Bridgette Mongeon

https://creativesculpture.com

At and Technology Podcasts coming April/May 2010

If you would like to use this article on your website you may. Please include the authors name and URL.

3D Printing In Ceramic! So Cool!

Too cool, 3D printing in ceramics! Yes. I love this idea. I love where the technology is going. Check out Ceramic Arts Daily article The Printed Pot. Solheim is on my list for interviews.

3d Printing In Sand And Metal!

I was invited by Bob wood to the proMetal shop here in Houston. We have another engagement for Bob to come to the studio as soon as my schedule frees up a bit.

I was thrilled to be able to see the process of printing in sand. Yes, there you have it… 3D printing in sand! As usual this technology was first developed for manufacturing as you see by this casting of this fly wheel thing.

I’m also putting some pictures up of their 3D digital printing in metal. This is another part of of the company. The skull was created that way. Yes, they say they can print in bronze or gold! I’ll be describing this process in an up and coming book.

The sand is like the investment cast on the mold. and it is printed in this huge machine that Bob Wood and I are standing in front of. If this process can be perfected to get smooth surfaces it can really take over the investment casting of bronze casting. The lost wax method would literally be history, and there would be no more storing all of those molds! YEAH TO THAT! plus once the art is computerized it could be made to fit piece to piece. In other words, the seams would be put together like a puzzle. in the computer aiding in the welding together. So cool. The possibilities of this are incredible.

I have to get through the Mudbox book first. But am chomping at the bit about starting this other book. It will cover all of the new technology of output from the computer, as well as getting items into the computer— Digital scanning. So excited!

Mud.. What?

What is Mudbox? It is a digital sculpting tool. Just in case you have not deducted that from my previous posts. Yes it is like sculpting in real physical form, but… it is in my computer.

here is a photograph of what the program looks like. You can see the sculpting tools on the bottom and you can work in layers as well. There are also textures that can be used. I wish I could write more, but for now I hope this suffices. I’m on a deadline for writing this Mudbox book and need to get back to my chapters.

Check out the gallery on the Mudbox forum to see some spectacular work created in Mudbox.

Check out Bridgette’s book Digital Sculpting with Mudbox

A Few Questions Answered

Someone who was reading my posts and may be interested in Mudbox had a few questions. I thought I should probably answer them publicly. If he had a question than others may as well. The questions are as follows.

“You mentioned having problems with Mudbox and your Mac. You added RAM, changed the graphic board, and then said something about the problem was the OS version 10.5.7. Were all these necessary to have the program run correctly or was it just the OS? If so, were you able to go back to 10.5.6?”

I suppose I should mention some of the history of Mudbox. We should go back to late 2007 when Autodesk, one of the leaders in 2D and 3D design and engineering software purchased Mudbox from the New Zealand company Skymatter.

The biggest competition for Mudbox is Pixologic’s Zbrush.Z brush Demo came out in December 2002. It is a good program but in my opinion, not as intuitive or easy to learn as Mudbox. Even so, once I have tackled this book project I do intend to devour Z Brush as well.

Autodesk is a big company and having Autodesk behind a program is a huge thing. Both my co-author and myself feel that Mudbox is something to watch. I’m thrilled to be in on the ground floor with our book. Digital Sculpting with Mudbox: Essential Tools and Techniques For Artists Publisher Focal Press.

I have to give Mudbox commendations for quickly making a Mac version. It took Z brush a long time to come out with a Mac version. It was released in June of this year. Mudbox mac verions came out in May.

Needless to say there will probably be some bugs in a new version, but really there has been very little. My biggest difficulty was a graphics card. There seemed to be little suggestions offered on the Mudbox site concerning a desktop computer running mudbox. But finally, I changed my card and feel confident.

Unfortantely the biggest problem with my card seemed to have nothing to do with Mudbox. But may instead be something with the operating system, as another person reported that the same thing happens with him using different software. The problem when using another program, say photoshop or and clicking on that with my mouse, and then going back to Mudbox and turning my model which is a option>left mouse key, the model would flip upside down and my other program would hide. It was infuriating at first and when I got my new graphics card and it sill happened I was so mad. But the work around is simple. I just need to remember to tap on the Cintq tablet anywhere before pressing down the option key and turning my image. Once I do that, No problem!

Much has transpired in the last few months concerning this project and working in Mudbox. We have a deadline with the publisher and no software. That was frustrating. How do you write a book without software for the Mac? For a while I was able to run Mudbox on the PC side of a Mac using bootcamp, but it was a little frustrating for me. Different keys etc. So, yes Mudbox is running fine on my Mac with 10.5.7

When mudbox for the Mac began to ship in May, I was elated. I’m not sure how many Mac users there are but there are definitely some at Autodesk as I have been speaking to them.

RAM

I didn’t really need the extra ram that I bought to use Mudbox. The specs say that Mudbox can run on 1 gig but 2 is recommended. It is very important for both my co author and I to be able to write a book with instructions on a program that any one can use. Sure everyone would like to ramp up their computers and push the program to the limits. But we are keeping the average user in mind. Not the studio designer.

My basic reason for getting more ram is that I am also doing audio and video, and really wanted to begin to do video tutorials using such programs as Mudbox or zbrush. with that… well I needed a little more.

Graphics card

Here is a stickler and there does seem to be more cards for PC’s than Mac’s. But this new card was not terribly expensive, and I am glad I got it.

I do hope that has answered some of the questions. Be watching for what happens with Mudbox. Thanks for the questions, and keep them coming.

For those interested my present configurations are.

Mac Pro Mac OS X 10.5.7

2 x3 GHz Dual-Core Intel Xeon

12 GB 667 MH DDR2 FB-DIMM

Was using ATI Radeon X1900 XT- it was buggy

NOW WITH NEW CARD ATI radeon 4870

Dual displays

20 ” display

20″ Cintiq tablet