Posts by admin

Gating Up And A Dip

on a shelf.They must be dipped many times.

I’m going to the foundry weekly to check on things and make sure things are looking good and that we are progressing on the sculpture. This week I saw that many of the waxes of the praying man were gated up. This means that wax rods were put in place for the gases to escape. Pouring cups were added as well. Then each of these pieces are dipped, many, many times. Depending on the humidity this can take several days. Other molds are having wax brushed in them. Still others are almost ready for a metal pour. The many pieces of the sculpture are in various stages of the foundry process.

sits in their molds while they awaiting the dipping.

of the chair are waiting my approval.

many coats of wax.

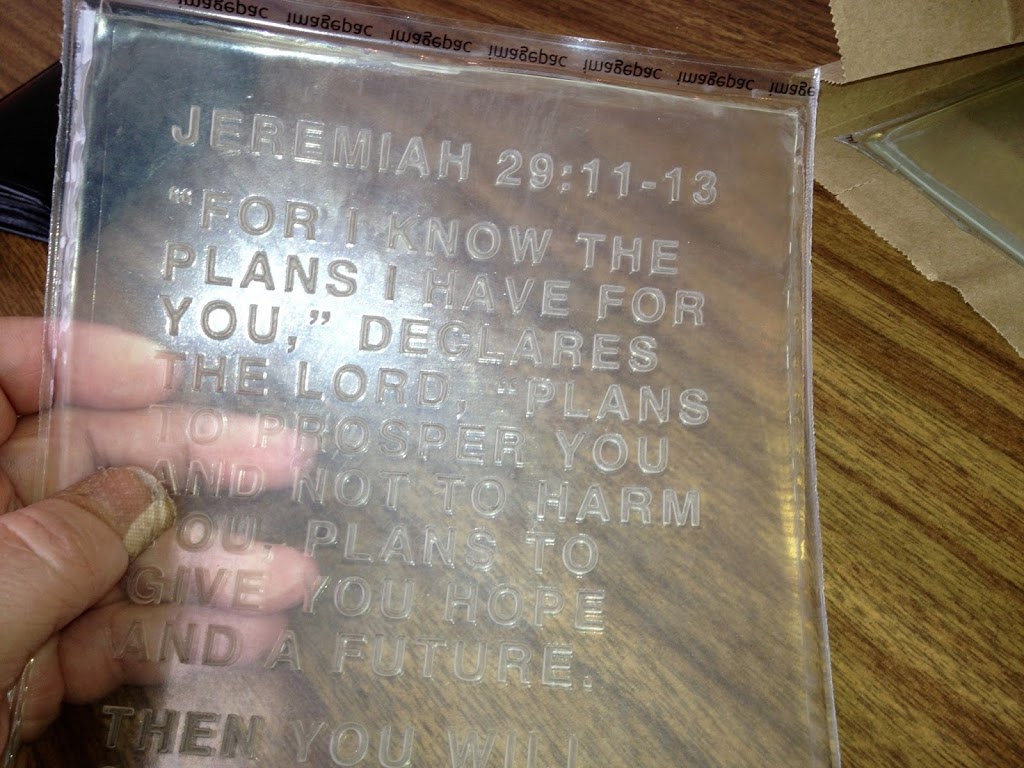

The Bible

The last and final piece to be complete for the praying man is the bible and seat. The biggest hold up with this was the text that was to be created in the bible. Usually I hand carve the text; however, this was three verses and quite a bit of text. After much deliberation I had the text created as a rubber stamp that is reversed, the type is indented into the rubber. I completed sculpting the bible and then put this stamp inside the pages, claying up to the edges.Then we made a mold of the seat and bible. THE FINAL MOLD IS COMPLETE! Everything will now go to wax and metal.

pages. Here is the seat after the mold was made.

clean the studio and get ready for the next project.

The text on the bible looks great!

Waxes—Gating Up

Once the waxes are poured and cleaned the foundry will gate them up. Gating is adding wax channels to the wax pieces so that gases can escape. A pour cup is also added to the wax.

Today I went to the foundry to check on more waxes and saw that a good deal of the praying man has been gated up.

Planning

It is safer for my interns and myself and

means that we are not held up by finding

warehouse space for a 15 foot tiger.

Now that we have the green light on the tiger I am spending a good deal of time planning. We are calling vendors and securing our schedule, and ordering materials. There was a bit of delay in getting the green light so we have to start over in this planning stage.

Besides planning vendors we are also planning the armature. Planning an armature is an important element to any sculpture. I always tell students, “if you armature is bad it can ruin your entire sculpture. ” Just imagine you are working on a large sculpture and all of a sudden it begins to fall over. In the case of the tiger, it could actually hurt someone.

An armature is what is inside the sculpture to hold it up while we are working on it. It takes a bit of engineering and a bit of history to know exactly what to do when building an armature. While I plan I send my plans off to others for them to look at and weigh in.

The main body of the cat will be milled out in foam. The foam, when it is together will probably weigh in at about 160 lbs. We will be adding wax on top of this as well as clay. This may add approximately another 300+ lbs to the piece. That is a lot of weight to be so high in the air.

The rocks are another element that has to be created. This will most likely be sculpted out of a different type of foam and then covered in clay.

We are still figuring the best way to sculpt this tiger. The artist in me says let’s put him together and work on him, which means I need a warehouse that is about 15 feet and have to move my entire studio. I like the idea of being able to see him all together. It also means I’m sculpting very height in the air, on ladders and scaffolding.

Another thought is to sculpt him in two pieces The first piece will be the rocks and his tail and back legs. The second piece will be the upper half. This way it is much safer for myself and my interns. I’m leaning in this direction. Though we will have the basic shape of foam and tiger put together before we separate these two pieces. So we will be able to see the design as a whole.

More to come. Meanwhile we are finishing up our last project and moving things around getting ready for the tiger while the vendors are getting our foam ready. Time before we receive foam should be about 3 weeks.

Waxes- Cleaning

or with larger molds they brush it in. Then because the molds

are in two parts each wax must be cleaned. Blemishes from

the pouring process and seams are removed.

Today was a day at the foundry. Once again, most artists don’t go to the foundry and look at their waxes. I suppose it is because I’m a perfectionist, or maybe I have a hard time letting go. I tell everyone it is because I might want to tweak something in the wax. Today I only had to do a little bit of tweaking. Here is the foundry process of waxes.

I’m headed back on Tuesday, maybe they will be able to take pictures of the next stage- gating up.

of the bronze- more on that later. Many people think that

when they see a bronze it is solid. It is not. This will all

make much more sense once you see the rest of the process.

ON YOUR MARK, GET SET, GO!… Wait Searching For Space

The sculpture details have all been ironed out! We can begin sculpting. I am presently trying to secure our schedule with the vendors. My first line of business is to find a temporary studio space as the tiger is much too big for my Houston studio.

I am presently searching for Houston warehouse space to create the Grambling Tiger in.

What I am looking for:

- Must have at least 15 foot ceilings as the tiger is big and with the rolling base we will need 15 foot clearance.

- No need to have a large door, believe it or not the tiger is cut up into many, many sections as we make molds for the foundry.

- Climate controlled is preferred, but may not be necessary if we can get going on this ASAP.

- Will need the space for approximately 3-5 months

- Need bathroom and running water at least on the premises.

- Concrete floor so that we can roll that tiger around

- A big enough area to work on tiger, get scaffolding around him and step back to check proportions from time to time.

- I’ll be working late hours so a safe location is also important.

If you know of such a space to rent please contact me and email your phone number. I MUST MOVE INTO THIS SPACE BY THE FIRST WEEKEND IN FEBRUARY- We start in February!

If you are an alumni and would like to be part of this project, please stay tuned to this blog. I will be looking for interns that want to be creative and assist in the building of the big tiger. This is a great opportunity for artists, but artistic propensity is not necessary, passion and commitment are. I believe any alumni will have that.

Mold Making

Interns are smoothing, cleaning,

and claying up. The place is quickly becoming

quite a mess.

The mold making process is a long and grueling part of the lost wax method of bronze casting. This part is usually done by the foundry. I enjoy having a bit more time to look at the pieces and see what more work I can do on them when I create the molds. Because of the time crunch on this project and my desire to tweak just a bit more we are making the molds in my studio. Now be careful, if you don’t leave the studio with some rubber attached to your clothing you will leave with plaster dust. I have until January 28th to get these molds done and out of the studio as I need to clean up the space for my daughter’s baby shower on the 2nd. Oh Lord, give me strength.

using shims. The advantage of this way of making the

mold is that both sides can be covered with rubber at the same time.

individual molds. Sometimes this is done by “claying up”

one half, then painting rubber on the portion.

step in gathering all of the detail.

rubber is covered with plaster must be separated.

The original artwork is taken out of the mold, the mold is

cleaned and then it is inspected, put back together and sent

to the foundry. Antoinette and Alison work on cleaning molds.

Bridgette Mongeon created this sculpture for Dallas Baptist University. If you would like to read the entire process on the artists project blog for this project visit http://prayingmansculpture.blogspot.com/ .

Going To Pieces

Don’t let this part scare you. It is what happens with every single sculpture that goes to bronze. We spend all of that time making it perfect only to cut it up into many, many pieces. This part is usually done by the foundry. My team and I continue on with this part of the process. I like to do this because I can tweak the sculpture even more. There will be more smoothing and working with the sculpture.

It is amazing how many, many pieces in a bronze sculpture.

Bridgette Mongeon created this sculpture for Dallas Baptist University. If you would like to read the entire process on the artists project blog for this project visit http://prayingmansculpture.blogspot.com/ .

together in the end.

They patiently await the mold making process.

Approval

It has been about a month since I physically started sculpting on the piece and just about 7 weeks since we met in Dallas to discuss the project. This is a miracle. I’m thankful that God has kept my health, as well as the health of all my interns in check. Dr. Blackburn and Shannen Smith come to my Houston studio to look over the sculpture. I’m elated when they tell me I don’t have to change the hair.

If you think cutting ears off is something,

just wait to when we get to

the mold making process.

all in. I’m pleased they are happy. Then I show them what is hidden in the shoes.

Bridgette Mongeon created this sculpture for Dallas Baptist University. If you would like to read the entire process on the artists project blog for this project visit http://prayingmansculpture.blogspot.com/ .

Some Thoughts-The Hair

Continuing our work on the Praying Man for Dallas Baptist University. You can find their project blog on Blogspot.

THE HAIR

I know that you had said you might prefer a different hairstyle. I do hope you will consider my suggestions and thoughts about the hair. I don’t believe I make these decisions for the art on my own; I do feel that there is meaning and intention that is greater than my own that goes into these details.

When beginning to sculpt the hair I tried a few different hairstyles. The wispy look of the hair is inspired by Jeane-Antoine Houdon sculpture of inventor Robert Fulton. I loved creating the hair. It was at night, the interns go home, and I am alone with the sculpture. It is my favorite working time because that is when I can “hear”the intentions that are coming from my hands. It is very similar to “feeling” direction after prayer while rocking in the rocking chair.I am pleased with the hair, and when asked if I could change it the thought startled me. I had to ask, why? Why God, why is this hair so important to me?I stepped back and said, it is full of emotion. It is just above the arms of the chair, and because it is full of emotion and motion it draws you in to the rest of the sculpture.

I sought more; this is an artist reason, but it felt a deeper attachment to this hair? Why? I thought of how I strive to change to live in God’s image. My heart reminded me that I go to my prayer closet to seek God, I am not perfect. It seems that in this sacred place of this sculpture the man should not be “perfect.” When I go to God in prayer I don’t have everything in place, I don’t have everything figured out. I come to seek God, just as I am. Sometimes, this praying time is easy, ritualistic, other times it is heart wrenching. I bring the loss of a child, a parent, and a relationship. I come seeking a deeper knowing of God, a direction. It is these times—as I am bending on my knees I am I am running my fingers through my hair as my knees hit the ground. “This is yours Lord, I need you, I can’t do this alone, I need your guidance, and I am only a man and not perfect. I will sit here as long as it takes, I am in earnest and seek my perfection in your grace. ”The man kneels, his hands resting on the word of God, the arms of rocker embracing him as he seeks.

You are the client, I will change the hair, in the wax to whatever you like; however, I do hope you will entertain and pray about the creative direction of the artist and the intent behind the guiding of my hands.

I look forward to seeing you on Monday. Bridgette