This Really Happened This Morning

— “You hoo. Are you up?”

Me: “What? Is it morning already?” ( I open my eyes momentarily, and then shut them again.)

— “Hey, hello, pay attention!”

Me: (I reach over to check my cell phone.) “What the …? It is 4:30 in the morning.”

— “I know you can see me. Come on, wake up.”

Me: “Who is shining a spotlight into my window, and what on earth do you want at 4:30 in the morning?”

— “I’m not a spotlight. I’m a desert full moon. If you thought the New Mexico sunsets were great, you should see me.”

Me: ”I’m sleeping, can you please be quiet and get your boney rays out of my eyes.” (I balance a pillow on the bed in front of me.)

— “Come on, I know you want to open the shades and look. I’m not like one of those Houston, city moons. I’m a full, winter, desert moon. “

Me: (Getting even more irritated, but now fully awake. ) “ Hey don’t diss our Houston moons. They are pretty great, and I have seen one or two at the end of my street that were so large they looked they could roll down the street and and bowl down all of the houses.”

— “Yes, I know, but this is a desert moon, aren’t you the least bit curious? Don’t you want to open the blind and let my magical powers flow over you while you are in bed. “

Me: “There are no magical or mystical powers in the moon. I really would rather sleep.”

— “No magical powers— I make tides. That is pretty darn incredible you know. Lets see you do that. Besides if you wanted to dance naked under the New Mexico sunset.”

Me: “Hey, how did you know, and besides, I never said I wanted to dance naked. I wrote.

(The sun sets, a crescendo of color and texture, clouds mixing with hills, fire in the sky. It makes me wish I had a drum or a fire, and I could dance and praise the gods for such delight. )

— “You should see me. I know you want to look. I’m quite stupendous. There are many things that are special about a full moon, in the desert, in New Mexico. Google it.”

Me: ”I don’t want to Google it. I don’t want to dance. I don’t want to open my shade. Please go away. Hey, quit moving around, peaking in and hitting my eyes with your brightness. I really want to sleep.”

— “No, I don’t believe you do want to sleep. You have an adventurous soul. I think you really want to take a moonlit walk in the desert.”

Me: “I barely walk in the desert at daytime. Nighttime? I’ll probably walk into a cactus. Wait, what am I talking about? I don’t want to walk around at night.”

— “It is not really night any more. It is early morning. And then you will not miss your buddy —the sun, he comes up just over there you know.”

Me: “Yes, I do want to watch a few sunrises, wait. I’M NOT TAKING A NIGHTTIME WALK.” (I jump out of bed and open the blinds) “There, I’m letting you in. Are you happy now. Please leave me alone. “ (I look up expecting to see the man in the moon with a menacing smirk, but instead I shriek) “Oh, my God ,I think you have burned my retina. What is wrong with you? (I cover my eyes, concerned with the damage I have just caused.) “That is a horrible trick. Are you sure you are the moon?”

— “Yep, Beaver moon. Google it. I know your curious to see if I’m telling you the truth.“

Me: “You are not big, but you are terribly bright. I expected more. I can’t even look at you. And… I’m not Googling anything. I’m paying attention. Isn’t that enough? Can’t I just rest here and let you do your thing? “

— “Beaver moon because I remind people to set their traps.”

Me: “I’m a sculptor and a writer. I live in Houston. I don’t hunt, and I think it is cruel to trap animals.”

— “Yes, but you were going to hike in the dark, lots of things are done during a full moon. It is an entirely different adventure. Come on, get up and walk with me.”

Me: “ You are relentless.” (I open my eyes.) “Good you have gone away.”

— “Nope, I’m just behind this pine. I’m still here, waiting.

Think of it… a moon walk, sunrise, hot tea, there might even be wildlife.“

Me: “Right I’ll get eaten by something for sure.”

— “Now you are being silly.”

Me: “Give me a break, I’m tired. It does sound tempting, Can’t I just close my eyes for a few minutes?”

— “Sure, but first take a picture of me like you do the sunset.”

Me: “It will never work, besides you are behind the pine. “

— “Yea, but I can see your feet, so just sit up.”

Me: “There. I told you it would not work. Please just a few minutes to rest my eyes. “

— “It’s a marvelous night for a moon dance. With the stars up above in your eyes…”

Me: “Are you really singing? You are not just annoyingly bright, but you are singing?”

( I pull the cover over my head.)

— “Yep and I’m shimmying as I sing, but you can’t see me because I’m behind the pine. Come on out and take a look.“

Me: (Silence)

— “Come a little bit closer

Hear what I have to say

Just like children sleepin’

We could dream this night away.

But there’s a full moon risin’

Let’s go dancin’ in the light

We know where the music’s playin’

Let’s go out and feel the night.”

(Pause)

— “… Hey, you still awake?”

Me: (snoring loudly)

(A banter with the moon, early morning hours. By bridgette Mongeon )

Private Gathering on Art and Technology

shared information about incorporating

3D technology in the traditional sculpture

studio at Shidoni Foundry. The lecture

culminated with a viewing of the cast

sculpture and a foundry pour.

As many of you know, I am in New Mexico approving the sculpture of the 14+ foot bronze tiger that I created for Grambling State University in Louisiana. It is being cast by Shidoni Foundry. I also gave a presentation at Shidoni Foundry titled Taming the Beast: A Lecture on Fine Art, Craft and Technology. The lecture is about the process of creating the tiger, but also about some of the items in the new book that I am writing titled 3D Technology in Fine Art and Craft.

My very gracious hostess here in Santa Fe, Mary Anne Stickler has offered to have private gathering in her home for some of her friends who are interested in art, and great conversation. I’m so honored.

Date: Monday, November 18th

Time: 4:00 p.m.

If you miss either one of these lectures and gatherings, don’t fret. I’ll be back this spring doing something similar in Albuquerque-details to come. Oh, and if you want me to come and speak in your area, just give me a call.

_____________________________________________

Bridgette Mongeon is a sculptor, writer, illustrator and educator as well as a public speaker.

Her blog can be found at https://creativesculpture.com.

She is the vice chair of the planning committee for 3DCAMP Houston 2012 and 2013 http://www.3dcamphouston.com

Follow the artists on twitter twitter.com/Sculptorwriter

Wrestling The Tiger

I’m headed to the foundry in New Mexico very soon to monitor the rest of the progress and to do the final coloring of the Grambling State tiger. Then we will load it up on the flat bed and watch for it to arrive on campus. Not sure how much posting I’ll be able to do while there. You will get glimmers of the sculpture in the snap shots that I take. Not until the great reveal will you be able to see the entire sculpture complete. Unless… you are in NM on November 16th. I’ll be giving a lecture on “Taming the beast” at Shidoni Foundry. The lecture will culminate with watching a bronze pour. (Not the tiger as it will be complete.) We will also be able to take a look at the finished tiger. I can hardly wait.

I’d be happy to repeat this lecture at Grambling for those who are interested. Looks like we are leaning toward delivery of the sculpture in the first week of December.

Rocking Out Again

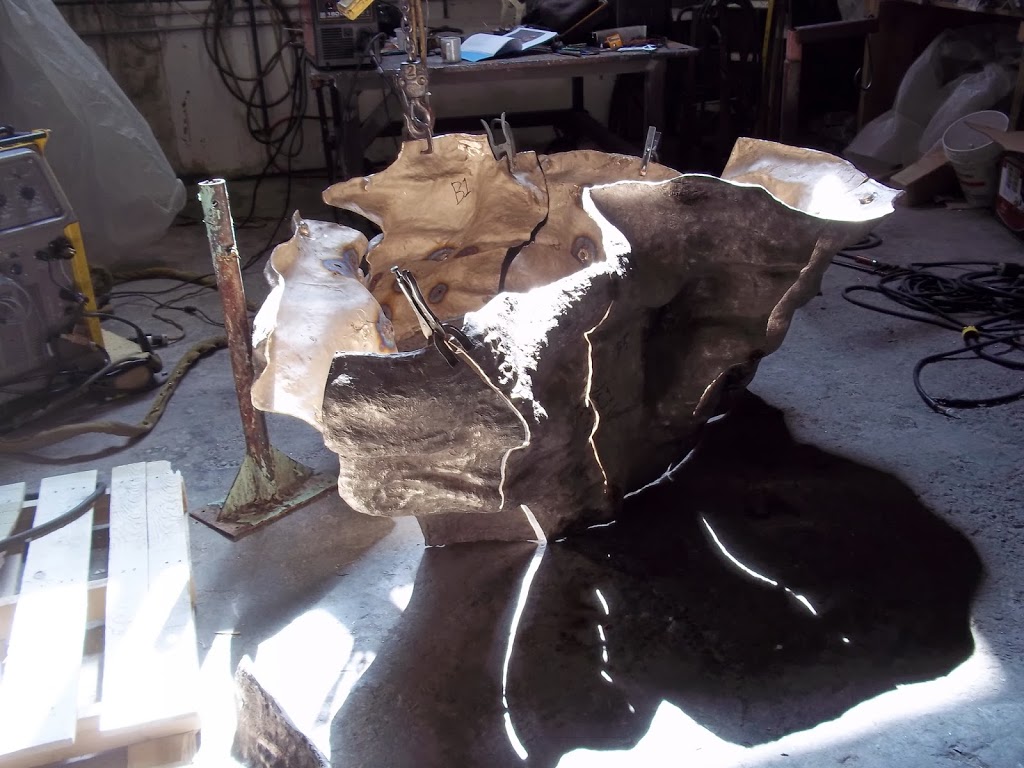

The rocks in this Grambling State tiger sculpture are just as massive as the tiger itself. The many, many pieces of the sculpture are being welded together. The foundry will match my sculpted textures. It is a huge puzzle to figure out where everything goes. There will also be an internal structure inside the sculpture to give it support.

Removing The Ceramic Shell From The Tiger Head

In the post we saw some the process of pouring the head of the tiger. Now that the head is poured, the ceramic shell must be broken off of the metal. This is called divesting. I asked the foundry to take a movie of this part. It looks brutal, but it is important. If you watch the entire thing be sure to look at the how they also much take the shell of the inside the sculpture.

The second part of this video shows them taking the metal spurs off of the sculpture. I especially like the look of this video. Seeing the light from the torch shine through the holes in the sculpture.

Now, this piece will need to be sandblasted to get all of the ceramic shell off of the metal.

Taming The Beast: A Lecture On Fine Art, Craft And Technology

Taming the Beast: A Lecture on Fine Art, Craft and Technology

Sculptor Bridgette Mongeon will be presenting a lecture on incorporating digital technology in traditional art and craft on Saturday, November 16, 2013 at 10:00 at Shidoni Foundry, 1508 Bishops Lodge Road, Tesuque, NM 87574.

Digital Sculpting, CNC milling, and 3D printing, combined with traditional sculpture, is the way that Bridgette tamed the 15’ tiger that she sculpted for Grambling State University. Shidoni Foundry in Santa Fe, NM is casting the beast!

Bridgette will be discussing the technology, her process and how others are combining the technology in art, craft and science. The creative event will culminate with a viewing of the completed bronze tiger and a demonstration of a Shidoni bronze pour. Space is limited. To reserve space for Taming the Beast contact Shidoni Foundry office, 505-988-8001 ex 114

About the Artist

Houston, Texas sculptor, Bridgette Mongeon, is a traditional figurative sculptor of over 30 years. Bridgette began to incorporate digital technology in her work in 2008 and coauthored the book Digital Sculpting with Mudbox: Essential Tools and Techniques for Artists. Writing and lecturing about; art, marketing in the arts, creativity, and digital technology, gives her great pleasure. Bridgette holds a BA from Vermont College and an MFA from Goddard. She is presently working on a new book about 3D technology in art and craft.

_____________________________________________

Bridgette Mongeon is a sculptor, writer, illustrator and educator as well as a public speaker.

Her blog can be found at https://creativesculpture.com.

She is the vice chair of the planning committee for 3DCAMP Houston 2012 and 2013 http://www.3dcamphouston.com

Follow the artists on twitter twitter.com/Sculptorwriter

3D Technology in Art and Craft – A Question- 3D Printing in Color

I’m working on a new book that details 3D technology in Art and Craft. It will describe how to create art using such things as 3D printing, 3D scanning, 3D sculpting and 3D milling. It will show how to combine these technologies with traditional art and craft. It will also contain interviews with businesses and artists to discuss their processes. Finally it will be a one stop book that features vendors and other resources.

I’m culling through my many years of research and writing on this topic. I studied 3D technology as it is combined with art as my MFA, and have written and lectured on this topic often. I’m also looking at the new technology that is coming out. In light of that, I thought I would post some of my own questions on the topic. If you have an answer to these questions please feel free to post in the comments section of the blog or drop me a line. Please cite your answers when possible. I greatly appreciate it.

3D Question- printing in color.

I’m intrigued with printing in color.

As part of the book I really want to walk the reader through creating a piece of art that uses 3D scanning and 3D printing as the art interacts with natural surroundings. I wrote about that in a previous post. I love the video created by Greg Petchovsky who takes objects in the real world and then recreates them or adds to them in a 3D program and then prints them out using a 3Dprinter. I contacted Greg about this project, asked him how he scanned the color and what other details he could tell me about the quick projects in the video. He was kind enough to answer some questions. Here are his comments from the e mail

had my prints done by Shapeways, they used ZCorp 3d printers.

The material isn’t waterproof, it will warp and develop white discoloration if exposed to water. I haven’t left 3d prints outside for a long period of time, so I’m unsure how long they would hold up.

I set up the scale in 3ds Max. I just used calipers to measure the object, but in future I’m thinking I’d include a wooden ruler in the scan.

I don’t think I’d use masks or visibility to make meshes fit into each other. I’d try to use booleans. I haven’t experimented all that much with booleans in zbrush, but basically there’s a button over each subtool that lets you chose between additive, subtractive, or intersection. And the resulting mesh can be calculated using the “remesh all” button… though the results might be somewhat mushy. I believe similar (possibly better?) results can be achieved with dynamesh? And I guess the details could be re applied using projection.”

I am also intrigued with the work of Laika and how the puppeteers created the pieces for the making of the movie Paranorman. Each puppet was created using different expressions. These expressions were used with stop animation and some computer graphic work to create the film Paranorman. I’m assuming the super glue will help to strengthen the piece as well as keep it clean.

It is reported by the University of Texas at Austin Architecture school, in this article that using super glue can double the price of a 3D printed piece. I’m still not certain what the process is of “dipping” a piece in super glue/acetone. Seems like it would make a mess and be very difficult to handle. I can’t believe no one has figure out another way to harden these materials. Also, it looks like none of these things printed in color can be used outdoors, so I may have to modify my example for the book to use drift wood instead.

I contacted one of my go -to people on 3D printing Paul Cesak, who just happens to also be the guy that started the 3D printing group on linkedin. The 3D printing group is growing by leaps and bounds. He replies “only with 3D Systems can a 3D print have the full spectrum of color. The downside of that is that it is printed on plaster, is very fragile, and has the texture of sand. Indeed small details are either not printed or are lost in the post-processing.”

I contacted one of my go -to people on 3D printing Paul Cesak, who just happens to also be the guy that started the 3D printing group on linkedin. The 3D printing group is growing by leaps and bounds. He replies “only with 3D Systems can a 3D print have the full spectrum of color. The downside of that is that it is printed on plaster, is very fragile, and has the texture of sand. Indeed small details are either not printed or are lost in the post-processing.”

Another artist that I will be interviewing for the book is Eric Van Straaten. This video shows his work being created. I’m not sure he uses anything to strengthen his pieces. I’ll let you know after we talk for the book.

I have many questions.

QUESTION: how does an STL translate color? I though STL files did not have color?

QUESTION: What 3D printers can print in color?

QUESTION: If this is done through SLS printing, how does the laser depict color? ( I’m wondering if this can be explained simply)

QUESTION: is there nothing else that can strengthen the pieces using this type of 3D printing?

_____________________________________________

Bridgette Mongeon is a sculptor, writer, illustrator and educator as well as a public speaker.

Her blog can be found at https://creativesculpture.com.

She is the vice chair of the planning committee for 3DCAMP Houston 2012 and 2013 http://www.3dcamphouston.com

Follow the artists on twitter twitter.com/Sculptorwriter

That Is One Hot Tiger! Pouring The Tiger Head

I could not wait to show you all this video. Here is a spectacular video of the pouring of the tiger head that was provided to me by Shidoni Art Foundry in New Mexico. They report that the tiger is coming along. This is the last piece to be cast in metal and has you have seen by previous posts it is coming along nicely. We will not have it there for homecoming, but will be delivering it later in November. I can’t wait to see it all together. More news later. Until then check out the pouring of the Tiger head.

VIDEO NOT AVAILABLE ON THIS PAGE- IT does show up on the Grambling blog page.

Rocking Out! Putting Together The Tiger Sculpture In Metal

There is still much to do with the tiger. If you have been reading this blog you have found that the process of creating a mascot is quite laborious. Here is the process with links, once again. Note: there are a lot of other posts of the process in between all of these links below.

- The First blog post –The beginning June 1, 2012 The blog begins.

- Design process June 17th – The designing and working on project begins long before the actually sculpting.

- Approval process January 23rd- Approvals and final paper work is received by client.

- Enlargement of Design January 23rd – The enlargement of the sculpture is being made into foam for us to sculpt on. Meanwhile we search for a warehouse to hold this big creature.

- Foam Armature arrives in Houston. The CNC milled foam gives us an armature to sculpt on and arrives in Houston in March

- Approval of Sculpture May 27th post. Which means we have sculpted this huge cat in 2 months! this would never be able to be done without the digital technology of CNC milling to enlarge the foam pieces. It is a huge accomplishment. There were many interns who worked endless long hours.

- Mold making The sculpture comes a part and we begin the first part of the foundry process the mold making.

- Molds shipped to Shidoni art Foundry July 27th They will finish the foundry process.

- Wax and Sprues or gates Beginning in August the Foundry makes waxes from the molds.

- Pouring of metal- The pouring of metal happens each weekend at Shidoni art Foundry.

This is what we have accomplished thus far. In the next few weeks the last steps will take place

- Welding

- Patination

- Delivery

- Installation

Here you can see that the many, many bronze pieces that are poured are now welded together.

Update

Someone pointed out to me today that this blog has not been updated in over a month.

I’m so sorry.

What I have been up to.

While Shidoni Foundry has been busy working on the tiger, I have been very busy with my own creative endeavors. For the last few months I have been putting together 3DCAMP Houston. 3DCAMP Houston. is a day long symposium on everything 3D. It crosses disciplines such as oil and gas, engineering, computer graphics and others. It is also used with my own passion- art. I am co chair of 3DCAMP Houston which was a marvelous success held at the University of Houston Architectural Department. It was a huge undertaking, I was also a speaker. My lecture was on Copyrights, Ethics and Responsibilities of 3D. I have been writing a book about 3D technology and fine art and craft and this lectures is from of my chapters.

I’m also happy to report that the Grambling Tiger head was displayed in the art gallery at 3DCAMP Houston. The art could be displayed because the show consisted of art that was created using some form of 3D technology. As you know by reading this blog, the tiger was first sculpted in the computer and then later it was CNC milled as it was enlarged, and then clay was added.

The Tiger update

I have spoken to both Grambling and Shidoni Foundry it is confirmed, that the tiger will not be at homecoming. Instead, I hear there will be a separate celebration at Grambling for the installation of the tiger.

I have been waiting on some more photographs and a video from Shidoni Foundry. I can’t wait to post those. I think they will be coming any day now. The entire tiger has gone through the casting process. The last piece that I was waiting for was the head. Now they have to put this puzzle piece together, create an internal armature and give it a patination. I am scheduled to come to Shidoni Foundry around the 11th of November. I will be monitoring the tiger the entire week at Shidoni. I’m not allowed to post pictures of the entire tiger together, until after the unveiling, but I’ll be sure to post some glimpses. The tiger, at this date, is scheduled to leave Shidoni Foundry on the 18th. It will be traveling in an open bed trailer from New Mexico to Louisiana. I wonder if anyone will spot it going down the highway?

Stay tuned for more information concerning the installation and celebration of the tiger.