Technology

First Art and Technology Podcast Complete- We Are On Our Way!

Yesterday I conducted my new podcast that I have created as a part of my research into “Bridging the gap between the traditional sculpture studio and new technology.” It will be located on my blog and our new website ( not up yet) Digitalsculpting.net. This site should be up by May along with the podcasts. It will be a community of artists offering a vast amount of resources on this subject. It was prompted by our publisher Elsevier and the new book on Digital Sculpting with Mudbox.

My first interview was with digital sculpting pioneer Robert Michael Smith. Monday I will interview Joris Debo from Materialise. My hit list for others in this podcast of Art and Technology are both artists, those in research and those providing the technologies for artists. I’m especially interested in things that are near and dear to my heart. All aspects of technology that help to create figurative sculpture, methods that will assist in creating a new type of foundry and bronzes, clay and the history of digital art, as well as the mix of math, science and art.

I am continually reminded how much this bridge is needed, by both the vendors and by those working and passionate about creating and the technology. As Robert Michael Smith said in our interview.

“I’m glad to see people like you are picking this up and doing it on your own now. This stuff really should be financed from a single source. There should be a single hub of information. “

The others on my hit list.

- The other artists involved in the Digital Stone Exhibit.

- Carl Bass CEO of Autodesk and a sculptor and involved with the Digital Stone Exhibition

- Synappsys Digital Services along with Shan Gray on the new process Data Direct To Mold used to create The American

- Christiane Paul Who wrote these articles about digital technology and sculpture. The were written 10 years ago. This is how I was introduced to Robert Michael Smith. I would also like to interview the other artists in this group who were working in this digital sculpting 10 years ago they are:

- Dan Collins

- Kieth Brown

- Michael Reese

- Derrick Woodham

- Christian Lavigne

- Curator of Design and the Elastic Mind at MOMA Paola Antonelli

- Someone from Solheim Laboratories at the Mechanical Engineering Department at the University of Washington about their digitally printing of clay and glass. I would love to cover one of their other collaborators with them. Perhaps Ron Rael @UC Berekely who asks in this post “Are we the first in the world to 3d print translucent Porcelain?” It does not take long to float through this blog and find another 6-10 people that I want to interview. and I must say I want to be able to print 3d ceramics in my studio!

- I love Robert Lazarini’s work and would be thrilled to interview him!

- Adrian Bowyer about RepRap Open source.

Robert Michael Smith also gave me an extended hit list. Please, if you know anyone who is interested in being a part, and of course those wanting to sponsor the site, send them my way!

Deceased, Alive or Animated- The Facial Action Coding System- So Cool!

FACS is the Facial Action Coding System developed by Paul Eckman. I studied this in my undergraduate work when I was writing about Sculpting the Deceased. I wanted to know how I capture emotion in my art, or why I “feel” some things from my deceased subjects. FACS is some of the science behind what I do and feel with sculpting the deceased. It is used in animation and is mentioned here in this video about how they did the face of Benjamin Button. I think this is fascinating.

Check Out This Artist’s Work—The Avatar Sculpts In ZBrush

check out this artists work. The avatar sculpts in zbrush http://www.zbrushcentral.com/showthread.php?t=079195 I was on the zbrush web site and found this. So cool to look at. I especially like seeing the people reference!

3d Printing In Paper?

A wonderful link for MCOR. MCOR is a Swiss company who has created a 3d printer that will print in paper. For those who know about 3d printing the cost of the materials going through the printer is a great expense. But in the case of paper, that is not as expensive.

A Great Book On 3d Printing

I just wanted to tell you about a book that has really helped me in my graduate studies. I hesitated in purchasing it because it was a little on the high side and the binding and photograph shown did not really make me feel confident in the contents of the book, but don’t let that fool you. Ed Grenda really knows his stuff, and I don’t think there is anything about 3d printing that is not in here. As long as he keeps up with the technology with further editions I would say it is a must for the shelf of any person interested in 3d printing. Plus his web site has numerous articles and boo koos of information. ( it also does not look very professional but don’t click away too soon. It has a wealth of information.) I was privileged to talk to Ed last week about some of my questions and my own research and he gave me some wonderful leads, which I will be sure to pass on here.

I also invited him to let me interview him for a podcast, should we decide to start up the art podcasts and talk about 3d, ( Which I am very excited about.). Anyway. Thumbs up on this book. I would highly recommend it.

Wonderful Conversations- Ton of Information

Last week Bob Wood from ex one put together a conference call between the following people and myself. As Bob put it.

The purpose of the call is to attempt to answer as many questions as we can for Bridgette who is researching information for a book that she is writing. I have had many conversations with her over the last year or so and she has toured our Houston RCT jobshop. To paraphrase what she is trying to ascertain from us is how a traditional sculptor can migrate into the electronic design and manufacturing world. As all of us know, it took us years to figure this out. Bridgette is trying to define the process so that traditional artists can become productive without having to go through a painful learning curve that may cause them to shy away from this technology.

HE knows me well. Though he also failed to say.I have pitched a second book idea, am writing articles on these subjects and a good deal of my graduate studies is around the process. On the phone were the following people. It was so great to chat with these very knowledgeable people. It was also good to be around 3D people who, when I told them that I wanted to get designs out of the computer did not say, “why do you want to do that?”

Bridgette Mongeon – Sculptor, Artist, Author

www.creativesculpture.com

Houston, TX

Chuck Gailey – 3D Designer, Architect- designer, Artist

www.otbdesignworks.com

Whitefish, MT

Gabriel Obregon – 3D Artist, Freeform designer

www.hybrid-learning.com

Pittsburgh, PA

Mike Orange – Prometal Production Manager

www.prometal.com

Irwin, PA

Bob wood

All I can say is I wish I would have recorded this meeting. You all know I have been doing Christian podcasts for a while. Don’t be surprised if you begin to also see some art podcasts posted here. I have everything set up for podcasts and my spotonradio.com station has another channel. Now all I need is the time.

More Metal Question.

I’m trying to get my head around the digitial printing in metal. In my November 22 post I have shown two videos. The second one though it says shapeways is exones process. I posted the first one because it helped to clarify things for me though I was told the first video is not really how they create their bronzes. Ex one tells me their bronze is Our bronze is 90% copper and 10% tin. I have been talking with them about collaboration on the book and project. This is something I received from the production company at ex one 60% stainless steel

40% Bronze

“We print in a bed of stainless steel powder layer after layer until the three-dimensional part is done. We cure that bed of powder and then we take bronze powder and wick it into the bronze metal. How this happens is as follows. The design that was printed has a stilt as we call it (nothing more than an appendage sticking out of the part). This is added before we print in the stl file. When we set up the furnace we take that stilt and touch the bronze powder to it. At a certain temperature in the furnace the bronze powder starts to melt. When that happens the bronze capillaries into the stainless steel. If you would look at the stainless steel object before the bronze in infiltrated it would look like your kitchen sponge. A sponge has holes all over it. Same principle for the stainless steel part. So in order to fill those holes we use the bronze which is a lower temperature metal to fill the voids. This is how it becomes a composite.”

My question would be this. How would this weld together? If you printed in pieces and welded it together could this be seamless? would the welds show over time? ( this is a horrible thing concerning a fine art bronze) I wish I knew a metalurgist who could look at an ex one piece and compare it to the Everdur bronze. I’m also curious how this “printed metal” will handle the outdoors.

Learning About Retoplogizing—An Excellent Video!

Can I Really Digitally Print In Metal?

This is an excellent video that discusses Powder Metallurgy.

I know it seems like it is something that is not affordable not doable for the average person. But shapeways is making this connection to the common artist, the every day guy. Check out this video

And their prices are extremely affordable. http://www.shapeways.com/

3D Camp Houston Was A Success. Next Year Bigger And Better.

It was last Wednesday that my husband invited me to the 3D modelers and animators meetup. I was interested in the presentation on Zbrush by Johannes Huber. It was there that I met David Morris. David told me about a project he had been working on for just 8 weeks. It was a 3D camp, planned for this past weekend. He envisioned a place where people could get together and talk about 3D. My husband Mike delaflor and I jumped on board.

David was doing exactly what I wanted to do. I had actually been thinking about this for a year. I was going to do it this fall, but instead decided to perhaps make it a part of my graduate practicum. I had already talked to Next Engine, who have some wonderful affordable desk top scanners. Ex One who you have seen in previous posts. I have been contacting them about their direct metal printing and last month I went to see there printing sandcasting Molds. Ex One said when I was ready to get this going they would try to get Shapeways on board. For those of you who don’t know about Shapeways they are affordable service bureau for 3d digital printing, and they too are now offering digital printing in metal!

My goal was to get some vendors there and also offer some informative lectures on different processes of 3D. Well David did just that with 3D camp. I’m so excited and totally impressed with this young man. I think you will see this 3D camp grow in the up and coming years. I’m looking forward to presenting next year, and hopefully get the above vendors to demonstrate.

This year I demonstrated the 3D scanner, though I must say it was a crowded area and hard to get a good scan with so many people bumping the table. Still I get was able to sing the praises of this scanner that we are reviewing and using in our up and coming book, Digital Sculpting with Mudbox: Essential Tools and Techniques For Artists.

I also had this video playing and my article that I wrote for Sculpture Review on digital printing and milling where I talked about the incredible advances of Synappsys digital printing and their Data Direct to Mold process that is being used on The American.

My vantage point of 3D is coming from a traditional studio and using it to create traditional art. I suppose my focus then is a bit different than the traditional 3D artist. My graduate studies at Goddard- A Master of Fine Arts In Interdisciplinary Arts is based upon bridging the gap between the traditional and the digital studio. That is my interest. Though I have to admit, programs like Mudbox and Z brush are very intriguing and I expect I will be using them much more in the future. Oh no am I converting? Still I like the clay under my nails and my heart longs for dirty hands.

I encourage others to get involved with 3D camp next year, and plan on attending. I’m expecting it will double if not triple in size with a year of planning, some more backers, and some good promotion. If you would like to be a sponsore, If you are interested in presenting or are a vendor that would like to show at 3D camp next year please feel free to contact me or David.

Great job David!

Some of my favorite things there revolve around output. This is a home made cnc router machine. To check it out further go to http://buildyourcnc.com/default.aspx

Many seemed to be interested in what a fine artist had to say in a 3D camp.

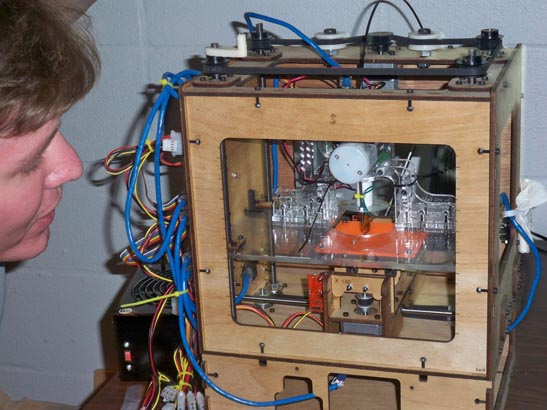

Another of my favorite had to again deal with output. It is the homemade 3D printer. This one is called the cupcake, and I must show that it can print a cupcake. I believe the cupcake costs about 700. to put together. There is another homemade one that I want to investigate but it costs approximately 3,000. Kind of steep to do for a hobby or to check out, but this other can print ceramic and chocolate, something worth investigating. I plan on reviewing all of these home made machines in an upcoming article.