Technology

My Armature Is Delivered To My Door

I had been away and out of the studio for a week and while gone I was happy to see that Synappsys Digital Services, took the digital work that I had done and created and milled out my pieces. Here is a bit of technical information for any artists seeing this blog post. Synappsys has two CNC milling machines, a 21inch z axis, and a custom one that they designed and built— a 3 axis- with a 8′ rotary axis. besides milling Synappsys Digital Services, offers 3d rapid prototyping. They are in Norman Oklamoma which does not pose that much of a problem for me as a Texas artist as I can send them my files and foam pieces are light and will fit in a wardrobe box.

The process

Foam is put on the milling machine and the machine mills out the digital file that I have sent to them. The entire reason for this process is that it saves me time in creating an armature. I also can figure out some details of the process, and design which has been discussed in previous posts.

______________________________________________________________

You can follow along with this entire process of creating a life size bronze for the ERJCC on the Evelyn Rubenstein project blog located at http://erjcc.blogspot.com/

Sculptor, Writer and Speaker

Bridgette Mongeon is a sculptor, writer, illustrator and educator as well as a public speaker.

Her blog can be found at https://creativesculpture.com.

She is also the owner and creator of the God’s Word Collectible Sculpture series

Follow the artists on twitter twitter.com/Sculptorwriter twitter.com/creategodsword

Facebook http://www.facebook.com/bridgette.mongeon

Listen to The Creative Christian Podcast or the Inspiration/Generation Podcast Click on Podcast Host Bios for a list of all podcasts.

Listen to the Art and Technology Podcast

Exporting ZBrush File For Milling

I have been on the phone with Synappsys Digital Services trying to figure out the best file, size and format that my digital sculpture of Evelyn needs to be in for them to work. This sculpture was created in the computer, will be milled out in foam and then created as a life size bronze. Synappsys Digital Services will be milling this out for me, but first I need to get them the file.

I have already decimated the individual files, with Decimation Master in ZBrush and I talk about this in a previous post. An important thing to remember is that ZBrush can create some very large files. Many companies that create output, for either milling or digital printing may not have the capability to handle such high resolution meshes. I have spoken to Synappsys Digital Services and they can handle 5 million or less.

To upload the file I have called Synappsys Digital Services and asked them to provide server information to upload my files. I must be able to upload them via Ftp. I use Fetch on my mac, which works just fine. With my FTP information ready, now all I need is the proper type of files.

Synappsys Digital Services can work with many different types of files. They can work with obj’s but their file of preference is STL Binary.

of all of my

subtools I can

merge them

down to create

one tool that

has all of its parts.

Obtaining OBJ’s are simple. While your Z tool or sub tool is selected go to Export and several file formats are available in the drop down menu. I need to export this sculpture in 4 pieces-both arms, the body , and the base. I will also want to combine the pieces and send it as one file. This way Synappsys Digital Services can see how each piece goes together. The reason why I want to separate the pieces is that if I combined all of them I will lose part of her hand as I realize that as it is placed on the digital sculpture the thumb is inside her body. I want to work with these hands more closely once I have them enlarged and sculpted. I need them separate and I need a thumb. They may also be milled at a different percentage to the rest of the body. They are more defined and so the hand/arm will probably only receive a minimum of clay on top.

Where as, the rest of the sculpture needs work.

To get an obj of all of my pieces I simply duplicated all of my subtools and then merged down these duplicated subtools together as one tool. Now I have both the subtools apart and one piece put together.

I have exported each an uploaded them up to Synappsys Digital Services but let’s see how the 3d Print Exporter plugin works in ZBrush.

Preparing ZBrush File For Digital Milling

I have worked diligently with this model. For ZBrush users or traditional sculptors entering the digital field, here are some things that I had to do near the end.

Perspective

Be sure that I was viewing this entire project in the perspective view. We traditional sculptors are not used to having to push a button to see in perspective, but these digital programs do. This should be done in the beginning to be sure you are sculpting correctly. This is basic, but check before you output.

Will my cut foam pieces align?

I had to fix the arms, as mentioned in the previous post. I need to fit these arms on the body and they will be milled at a higher resolution. I also plan to use less clay on them. I had sculpted them way under the sweater, instead I cut them off at the sleeve. I did this using Transparency to see through the sleeve.

Preparing Files

I will be sending this as 4 separate files- the base, the body, and the two individual arms. I might also combine them and send them as one file so that Synappsys can see how they go together. Though I do want them milled separately.

Before I can get these pieces ready there is another step I must do. Right now the files are very large for each. ZBrush has something called Decimation Master. Decimation master lets you hold your detail, but brings the file of each of the pieces down considerably

For example:

Before Decimation Master After Decimation Master

34% OF DECIMATION)

Right Arm

Active points 326,954 127,188

Left Arm

Active points 296,078 140,452

Body

Active points 7,751 mil 3,329mil 1,149 mil

Base

Active points 87,202 37,468

I can export the entire project and individual subtools, ie. arms, body and base as individual obj’s and then combine them as one obj . However, ZBrush also has a plugin that allows me to collect for output in the preferred .stl file for digital printing. Which means that I will have a different type of file for the vendor. In the next post I’ll talk about my experimentation with this plug in.

Ready To Send Sculpture For Enlargement

I have been working hard, looking at reference and learning about my new subject—Evelyn Rubenstein. I am documenting this process on a blog created for the Evelyn Rubenstein Sculpture for the Evelyn Rubenstein Jewish Community Center. I’m also posting some more detailed, technical information on my own Creative Endeavors blog. I have been using some of the new tools in Zbrush. Such things as Dynamesh which made my work much easier. The final sculpture will be milled in foam by Digital Sculpture Enlargement and Reduction and then sent to me. I will put clay on the foam and finish detail so that it can go through the bronze process. I thought I would give you a little 3 dimensional tour of this new piece before finalizing it for output.

Working On Preparing An Armature

I have been using zBrush to create an armature to send to Synappsys Digital Services for milling.

This is similar to what I wrote about in Digital Sculpting With Mudbox: Essential Tools and techniques for Artists, and what I have done with the panther project; however, I feel I’m pushing the process a bit more.

Here is the digital sculpture almost ready for the milling process. I believe I am going to send it to them but would like to separate the arms from the sculpture. The reason for this is that in the digital sculpture if the hands are sent with the body as one file they get lost in the clothing. I would like to determine their placement without losing details. Synappsys will separate them anyway within the process of getting the pieces ready for milling.

I’m not sure what will happen with the pearls. I doubt these can be done, and might actually be better for me to sculpt them on her. In fact, I’m leaning in that direction. Having them on the sculpture while working digitally has helped me with size and proportions. I have a few more things to do to the sculpture, and am anxious to hear what Synappsys thinks.

I SPOKE WITH SYNAPPSYS

Here are some of the things we discussed. As mentioned in my previous post, this Dynamesh is acting similarly to what Synappsys’ program will do when it lowers resolution. I have been requesting that Synappsys to mill out several heads that show either different resolutions of milling or different reductions. I am hoping to include this in my up and coming book, 3D 2012 digital art in a physical form. This will be a very important visual for artists to understand this entire process.

Some thoughts as Synappsys and I spoke

- The arms are created as what zbrush calls a “sub tool” I can separate them for milling , but I should probably be sure that they are cut and align evenly with the arms. Presently they sit within the sleeve. If they are a clean cut, and can match up, preferably somewhere in the arm where the sweater is, where I will have more design wiggle room, that will be better.

- It is almost paralyzing to try and figure out what size to mill this out at. There are several variables. If I want to add a lot of clay in the traditional studio , I have to allow for that mass. This may mean that I want to reduce the size. I may want to add little clay to the arms and hands, and up to 1″+ amount of clay to areas like the sweater, skirt, hair etc. So, I might have the pieces milled at different sizes.

- But the size problems don’t end with milling. In the traditional process of bronze casting of a life size person, it is known that artwork shrinks. My foundry indicates that I could lose up to an inch in size. But often times, the foundry can make this up as they are welding the many pieces together. Another aspect of casting in bronze is that “some pieces can shrink in the center, or look skinnier,” says Scot Yoast of Art Foundry Houston.

The entire concept is frustrating for an artist who goes through great lengths to sculpt a perfect or near perfect sculpture and have such deformations. My heart gets excited when I think about how digital processes are infiltrating the lost wax method of bronze casting and how this will change in the near future. A subject that I have discussed quite often on this blog, and I will go into great detail in my new book For now, I’m having to work this tra-digi art in any way that I can to get the results I desire.

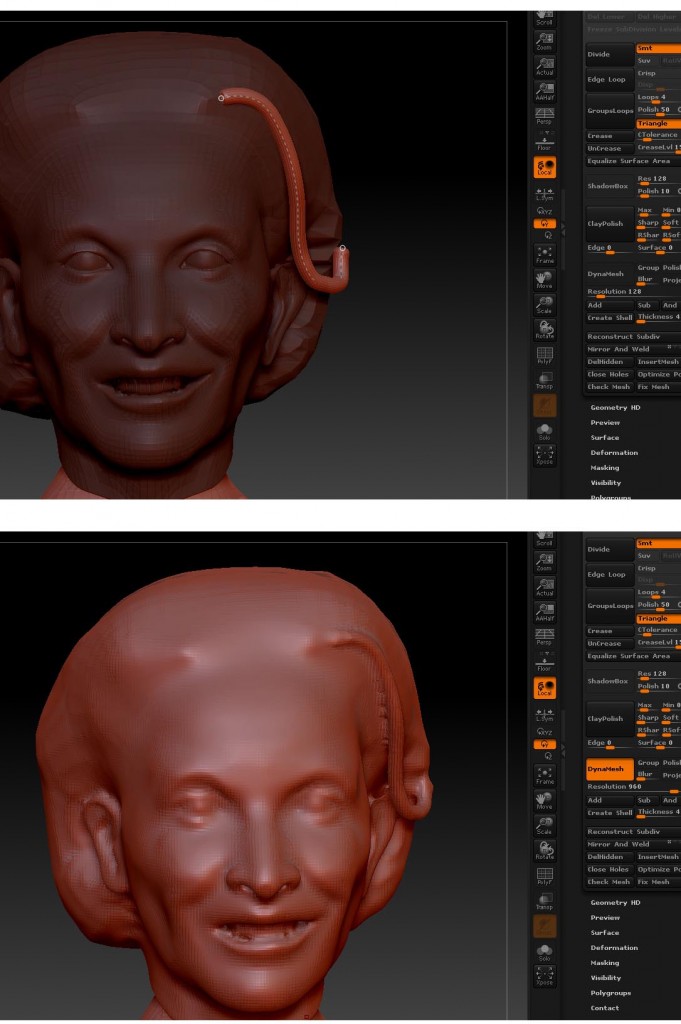

ZBrush And Dynamesh

As I prepare a digital model in the computer that will be enlarged and milled in foam by Synappsys Digital Services I am playing with settings. At this point the sculpture is in Zbrush and I’m working on creating the mass where I want it. I want to do a mjority of my sculpting in the traditional clay, and not have it totally milled in foam in great detail.

I like being able to spend time on the body shape and head shape and flip it around in my computer, comparing my phtogoraphic referece to the shape I’m creating in the computer. This is much easier than standing on my head downstairs in the traditional sculpture studio.

I’m also playing with a new feature in zbrush called Dynamesh. I have mentioned this elsewhere on this blog. Dynamesh is a button that remeshes the entire sculpture to fix any problems with the mesh. It is a good thing to have, but because it is new, I’m trying to learn how to use it.

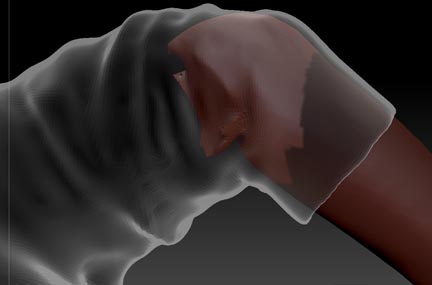

Double click on the photo on the right and you will see the top photo is my head in the original, the second from top remeshes using Dynamesh at 648 resolution, the next at 904 and the last at 1024 the highest setting. I’m wondering if this is what is done at Synappsys. It is hard for an artist to visualize how much of their form will not show up depending on the resolution and the size they ask Synappsys to mill in.

If you are interested in reading more about Dynamesh at Pixlogic- here is a link

HAIR using new tools

Another new tool in zbrush is a curve tube. I wondered If I could use this curve tool along with Dynamesh to get a better form for my subjects hair. Seems like it will be highly possible, if I want my sculpture remeshed. Here is an example of using curve tube and dynamesh. Notice

you have control the tube while it has the dotted line, then simply smooth it into the hair once it has been added to the original mesh with Dynamesh.

Getting to Know Evelyn

This is from a blog I am doing for my client on this project. The Evelyn Rubenstein Jewish Community Center Sculpture Blog.

Reference

Yesterday, my client was kind enough to take time with me and allow me to thumb through old photo albums. It is interesting… I’m looking for photographs of my subject, but it is seeing the family photographs, hearing the stories, this is what makes me feel bonded to my subject.

I’m trying to not only capture a likeness, I’m trying to find Evelyn. Watching her playful side in photographs, some that I have never even taken as reference, hearing about her parents, my clients and the relationship to them, even talking about death. All of these things add an element to a sculpture that you can’t get by just “doing the work.”

I once heard an artist say, “posthumous sculpture is just another commission.” It is so much more to me. This is a life lived. It is someone’s mother and wife. It is a person whose life made a huge difference and will continue to make a difference. How can I honor that? Who are you Evelyn?

My client also took time for me, and posed in a similar sweater like Evelyn is wearing in the key photograph. I needed to see folds all around. Folds are so important. In a recent sculpture of a young man playing ultimate frisbee I hired a young man of similar size to be my model. He spent an hour jumping up and down in the yard of my studio while I took video. Photographs were impossible as I could never catch the folds I needed when he was at the high point of his jump. So I filmed him, and then took stills to use as reference.

I could have had a friend pose for me, in a sweater like Evelyn’s, but even this little detail of having someone she knew and love pose, this makes a difference. We are cocreating. This is not just “my” artwork it becomes “our” artwork.

I’m becoming intimately familiar with the stature and physical nuances of Evelyn. I study the photographs. There are photograph from many different ages. Some are taken at 20- 50 even 70 year of age. This process is much easier at this age. Once I had to do a sculpture of a little boy who had passed away, the reference photographs I had spanned from ages 1-4 and 7. A child has huge changes in facial and body structure at that age. This is not so much with a grown person.

I’m spending time today tracing some of these photographs. I can set them over my digital sculpture image the way I would use them comparing them to shape and form traditionally in the studio. Again this process is giving me the general shape of Evelyn, so that I can have it enlarged for an armature to put on the clay. Tracing these images helps me to see the basic shape without a lot of visual disturbance.

Length of Skirt

My client helped to confirm the length of the skirt. We changed the length and, as mentioned in a previous post, the height of the figure. Much more to do on this model before sending it off. My goal is to have it to the enlarger before I leave town at the end of the month. That way, if I am lucky, the armature will be waiting for me upon my return.

on details for my armature and model.

I can’t wait to get my hands dirty.

All of the digital preparations are nice,

but I long to be with the piece physically.

Thinking

I’m looking at the pearls and wondering, where did she get them? My husband gave me pearls. I don’t wear jewelry, not even my wedding ring. It is hard to wear jewelry when you have your hands in goo most of the time. But pearls are all I wanted, a simple strand to wear when we go out. So, I think about these intimate details as I work on the sculpture.

Some of my thoughts, broad back, slight overbite, questioning her earrings, thinking about how she brushed her hair, who did it for her?

The Completion Of A Project

I have been working on this project for a while now. I really like how it turned out. Some of you may remember I posted about using digital techniques on the creation of this design.

A father commissioned me to creat this for his son as a graduation gift. I love the movement in this piece, there is not a bad side. It is rare that I want to own one of my own pieces, but I really would like to have one of these. Limited edition of 10.

Here are some links to the process.

Working through presentations Daz-Poser-Zbrush- Part 1 and 2

The final results of the presentation using DAz, Poser, Zbrush and Photoshop

Panther Project-The Process of Sculpting

outside keeps the studio dust free. It looks like he wants to go in the doors.

This is the work in progress for the Prairie View A & M Panther. To watch the process from the beginning please click to previous posts.The sculpting of this project is a quick turn around. We need to finish the panther in 18 days. This is day 2,3 and 4 of the sculpting of the panther. The previous posts state that this is a foam armature that was milled and sent to us from Bridgette Mongeon Sculpture Design Studio’s digital design. A great deal of carving is done on this foam, indicating muscles and action before it is covered in clay. The process is messy and requires constant vacuuming and masks, but it is coming along.I loved being able to attach the tail. You will see that the tail is much different from the original design.

More foam is added to thicken areas. Other areas are carved.

when using urethane foam.

UPDATE- COUNTDOWN BEGINS!

* The Sculpting process begins. The foam is soft and allows me to carve into it before we add the clay. The foam piece becomes the armature that the clay will be added to. Muscles are sketched in and now I begin the process of roughing in the body. Friday 3 people are schedule to put the two layers on the foam. one is wax to seal the foam the other is clay. I hope I can be ready. These are long gritty days. I could use some Prairie View A & M cheers here. Just 16 days before I am hoping to get approval.

This is a sculpture for Prairie View A & M University in Prairie View, Texas of their mascot the Prairie View Panther. The entire process is being recorded on a special blog designate for this project and can be found at http://www.prairieviewpanther.blogspot.com/